MTU Aero Engines: Monitor Your Entire Production Network With Track & Trace

MTU uses KINEXON OS to monitor the movements of all its manufactured parts in real time. The new system has been driving transparency and efficiency gains from day 1.

Guest writer: Tobias Weidemann

Knowing exactly where to find things is essential, whether it’s a custom-made part, an urgent production order, or the last few modules required to reassemble an engine after maintenance. That’s the thinking behind a project MTU Aero Engines has been working on for the past 18 months. The project’s goal is to obtain a comprehensive, real-time overview of every part that is produced and every repair job that is carried out on MTU’s premises. To achieve this, the company has decided to set up a comprehensive track & trace solution. In addition to ensuring full transparency of all on-site manufacturing processes, the new system also drives medium-term efficiency gains in material flow and production operations, thanks to the digitalization and automation of key processes.

So what’s the basic idea behind track & trace? As the name suggests, it’s essentially about maximizing transparency in intralogistics; that is, the logistics flows of goods and materials both on- and off-site. An efficient track & trace system continuously monitors the location of individual parts, component assemblies and even entire engines while automatically logging their route through the various stages of the production process. “In the past, much of this information would have been unreliable, and all of it would have come with a time lag,” says Lucas Burgey, project manager for MTU. Before the introduction of track & trace, workers recorded the production steps performed on a part and its journey across the shop floor by entering data in the relevant software. In some cases, however, this data would already be obsolete or simply be inaccurate — a pallet or container may have been moved to create more space, or simply because intralogistics or shipping processes hadn’t been logged.

Real-time positioning and tracking

Planning for the logistics 4.0 project got underway in late 2020. One of the first steps was to install numerous transmitters, or “beacons,” in the production facilities to enable real-time positioning and localization. Initially, the site tested out a simple position-tracking system for cage pallets and drawer cabinets, “just to get some basic experience in using the technology,” Burgey says. In addition to tracking their location, this trial system also provided information on whether containers were full or empty. After conducting a detailed analysis, MTU opted for an ultra-wideband (UWB) system. This short-range radio technology can locate objects with up to 10 centimeter precision, a level of accuracy that met the company’s requirements.

Track & trace caters to many different applications, but at the heart of all of them is KINEXON OS. This operating system integrates all location data and combines it with floor plans of the production facilities, maps of the company’s premises, and any production data and rules that have been stored in the system. All this information can be accessed and managed from a standard internet browser, which means users can enjoy all the benefits not just on their desktop PC, but also on a tablet or work smartphone on the shop floor itself. “You can carry around all these features in your pocket without needing some kind of special industrial device,” says project manager Martin Roth, who is responsible for the IT aspects of the KINEXON OS implementation.

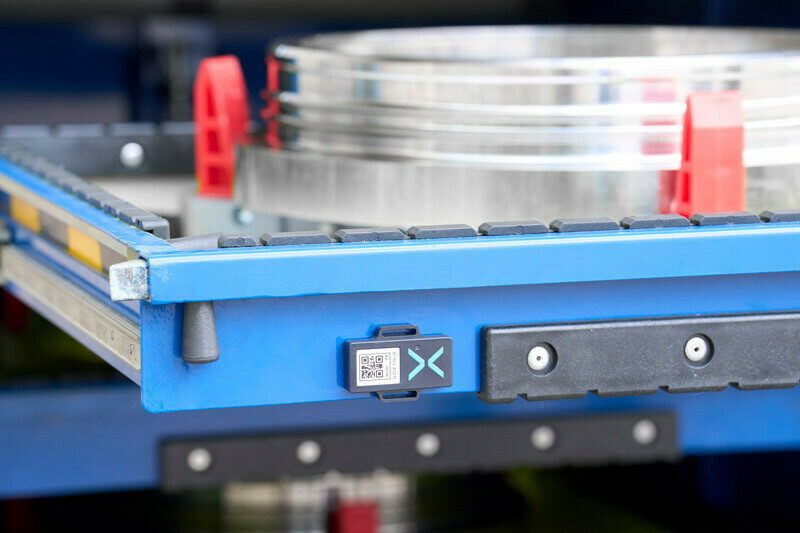

Apart from the software, the other key element of the system is the multitude of receivers, which are known as tags. Currently, these are KINEXON’s UWB-based X‑Tags. Roughly the size of a USB stick or a lighter, these can be attached to a drawer cabinet, pallet or picking cart to track their precise location. The company also plans to incorporate “smarter,” more complex tags to gain access to additional information.

“The advantages for the processes in our production are clear, but we’re also seeing some major benefits for our maintenance and repair business, which is intrinsically more volatile and therefore less easy to plan.”

Benefits for engine maintenance and repair

“The advantages for the mostly standardized processes in the production hall are clear, but we’re also seeing some major benefits for our maintenance and repair business, which is intrinsically more volatile and therefore less easy to plan,” says Yannick Dix, a project manager who is responsible for implementing the system at the Hannover site. At MTU Maintenance, engines are regularly disassembled into thousands of individual parts before being repaired and reassembled into a functioning engine. “Right now, this process relies on a lot of analog, paper-based methods,” Dix says. “The first thing we decided to do was to track the material-handling equipment that we use to transport and deliver picked engine components to the assembly area.” In the future, this process will also incorporate automated guided vehicles (AGVs), which will be equipped with vehicle tags. Later on, the company also plans to tag commonly used tools as well as some of the larger modules of dismantled engines to help workers find what they need quicker.

Track & trace is only the start

Once the UWB beacons have been installed, MTU will be able to use them as the basis for planning a wide array of additional Internet-of-Things applications and for implementing location-based process automation in their production.

“The first step is to track fixtures and machining tools, then we can move on to tracking repair jobs and managing other resources. But this is only the start of the journey.”

Over the next few months, MTU intends to gradually equip all its other locations with localization technology.

In the medium term, the company is also planning to add a variety of other tracking solutions. UWB can achieve impressively accurate positioning results on the MTU premises, However, there are also cases where the company might need to track the location of an asset off-site, which can be achieved using Bluetooth data and traditional GPS services.; for example, when an engine is being moved from one location to another. The location data acquired by these systems can also be processed within KINEXON OS, thereby providing the company with important additional information.“The new system is part of a broader automation and digitalization strategy,” says Burgey.

“In the future, the real-time data and information collected by the system will give us a more efficient way to manage and plan logistics concepts along the entire supply chain. This won’t apply just to MTU parts, but also to all sorts of other resources, such as tools, fixtures and any other materials that MTU uses to add value.”

Location-based services can then be harnessed to optimize operating times, reduce costs, and foster optimization and control of processes in the production environment — “all with a high degree of automation and growing intelligence, thanks to increasing amounts of data from a variety of sources,” Roth says. He notes that the number of use cases they have developed has already reached the high double digits, with varying levels of complexity. Dix says, “The overall vision is to tie together the physical and digital worlds without human intervention, enabling support processes such as transport and ordering to be launched and logged automatically. The time and efficiency gains will benefit everyone involved.” The fully autonomous flow of materials may still be a vision, but the technology is already laying the foundations for numerous exciting use cases on the path toward the digital factory.