Container Management

Automated Container & Load Carrier Management for Smarter Manufacturing

With millions of containers used in manufacturing environments around the world, inefficient container management wastes time and money. Automated container management uses precise RTLS data on container location and status on the shopfloor to improve overall container transparency and utilization. Automated container management also enables automated bookings and secures flawless process documentation.

Automated Container Management: Simplify Your Intralogistics with Location Data

In this 30-minute session, you will…

- Discover the full benefits of automated container management for faster production & assembly

- Understand how using location data for load carrier automation can help save time, money, and resources

- See its application live in the KINEXON Experience Center

How does RTLS container management solve key challenges in manufacturing?

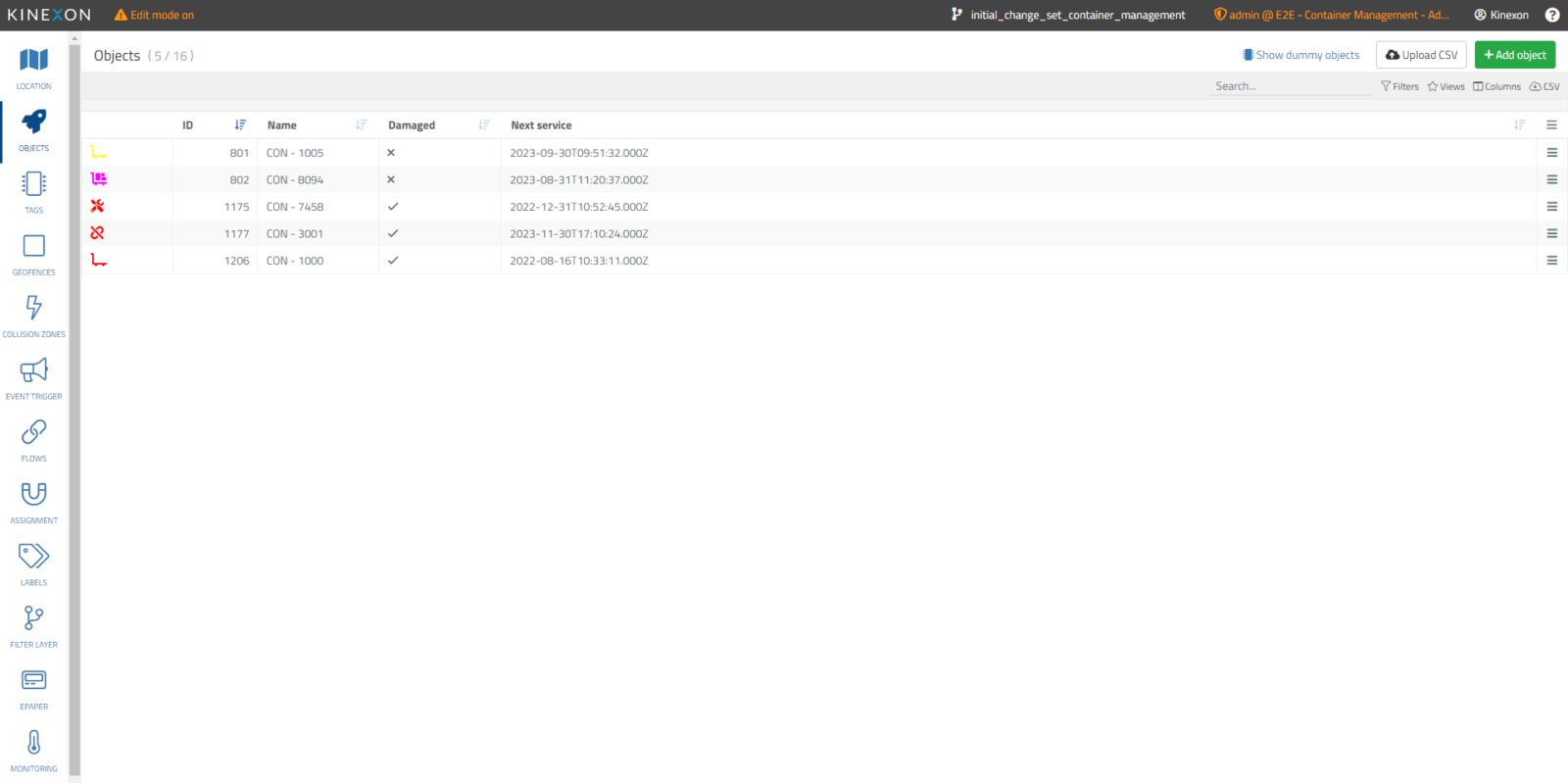

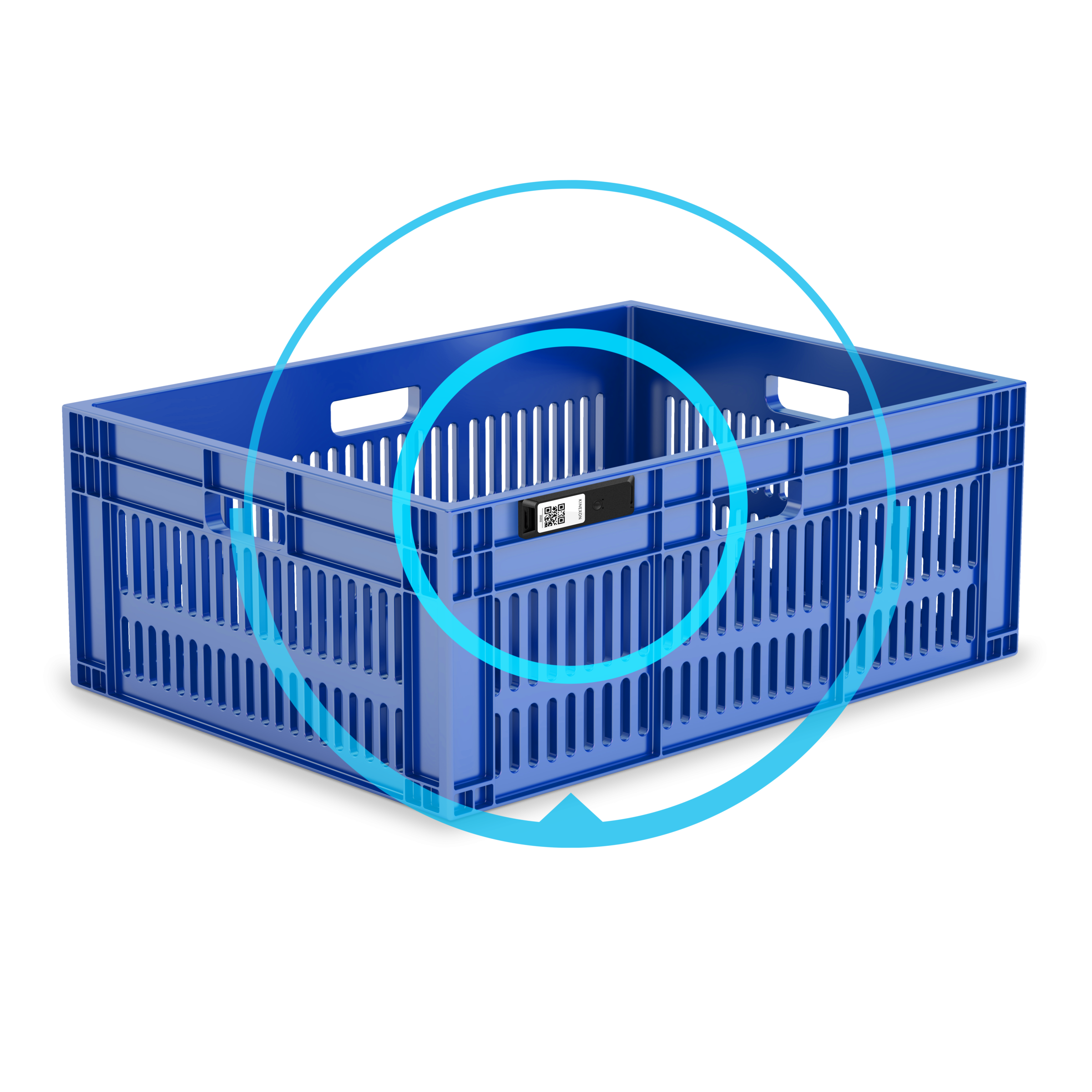

Automating container or load carrier management improves overall inventory management, cycle time, and process documentation. Having real-time transparency about the status and location of containers such as crates, small or large load carriers, pallet boxes or pallets, reduces time spent searching for containers and eliminates production bottlenecks. This allows manufacturers to cut cost and lead time in their assembly and production processes. Automated container management eliminates non-productive search and idle times as well as transportation and inventory cost through demand-driven replenishment.

Common types of containers for indoor use

- Crates

- Pallet boxes

- Large load carriers

- Small load carriers

Manufacturing more with less

The value and benefits of process automation in industrial production

How does container management work with KINEXON OS und KINEXON RTLS?

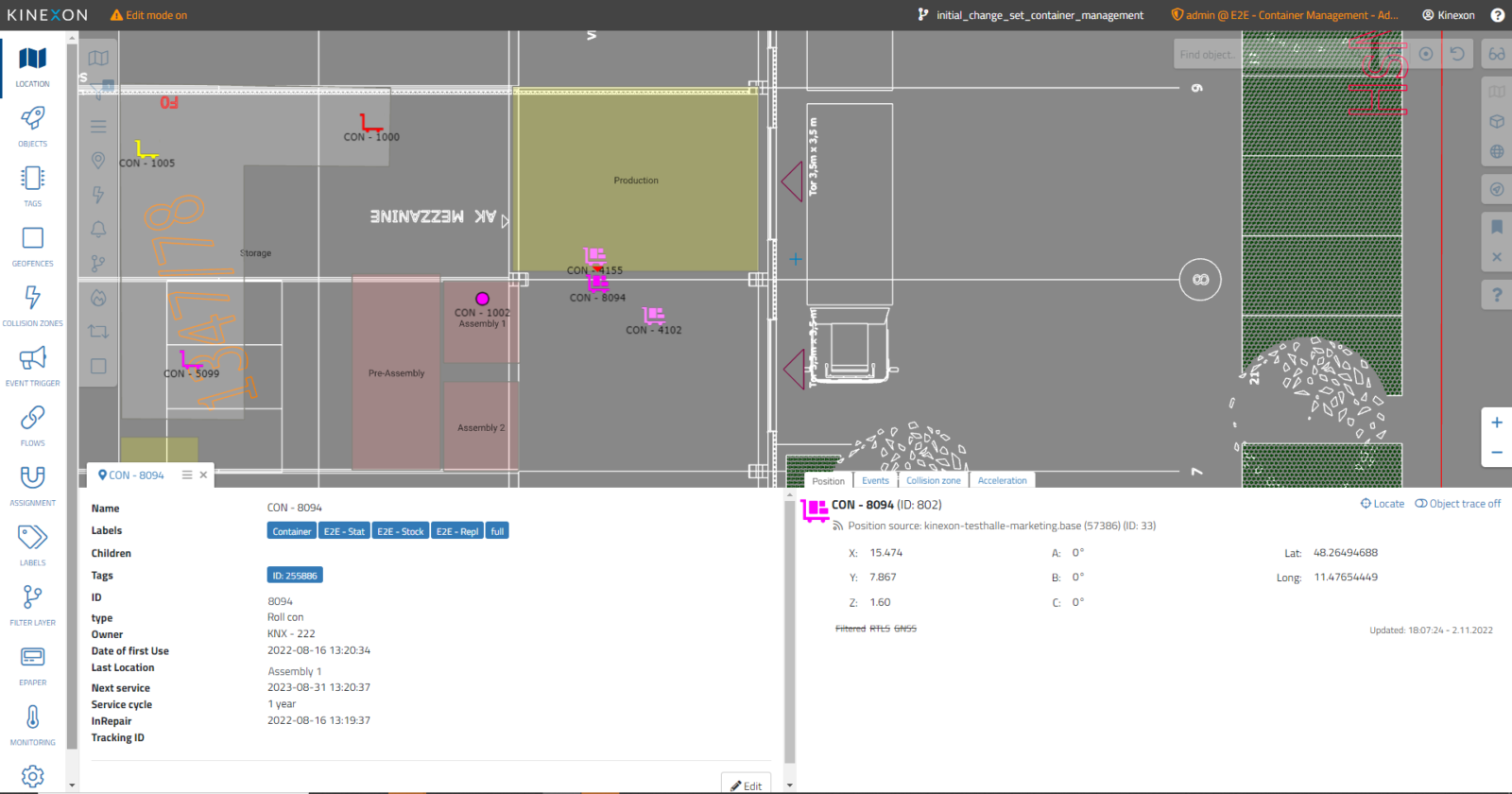

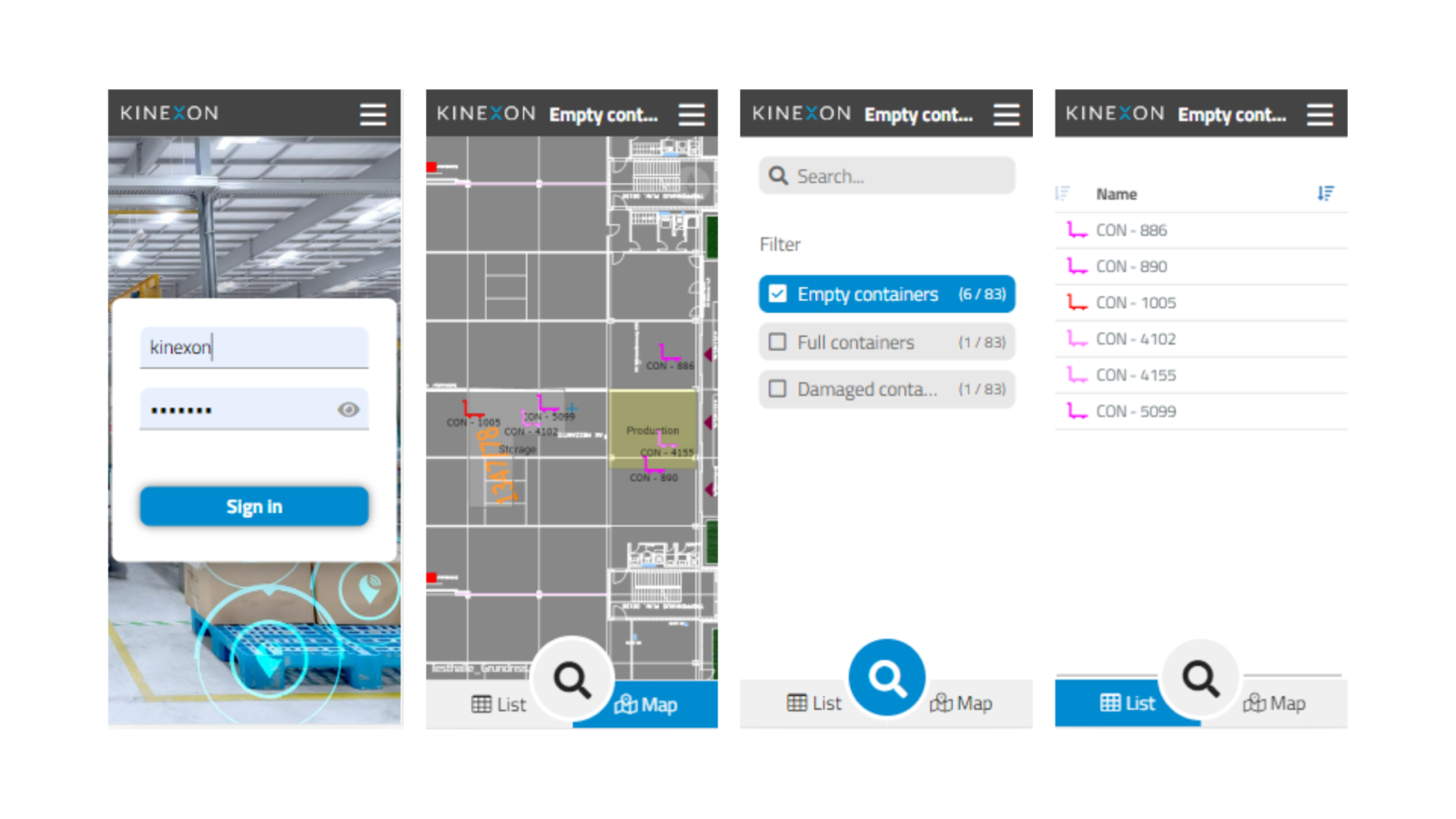

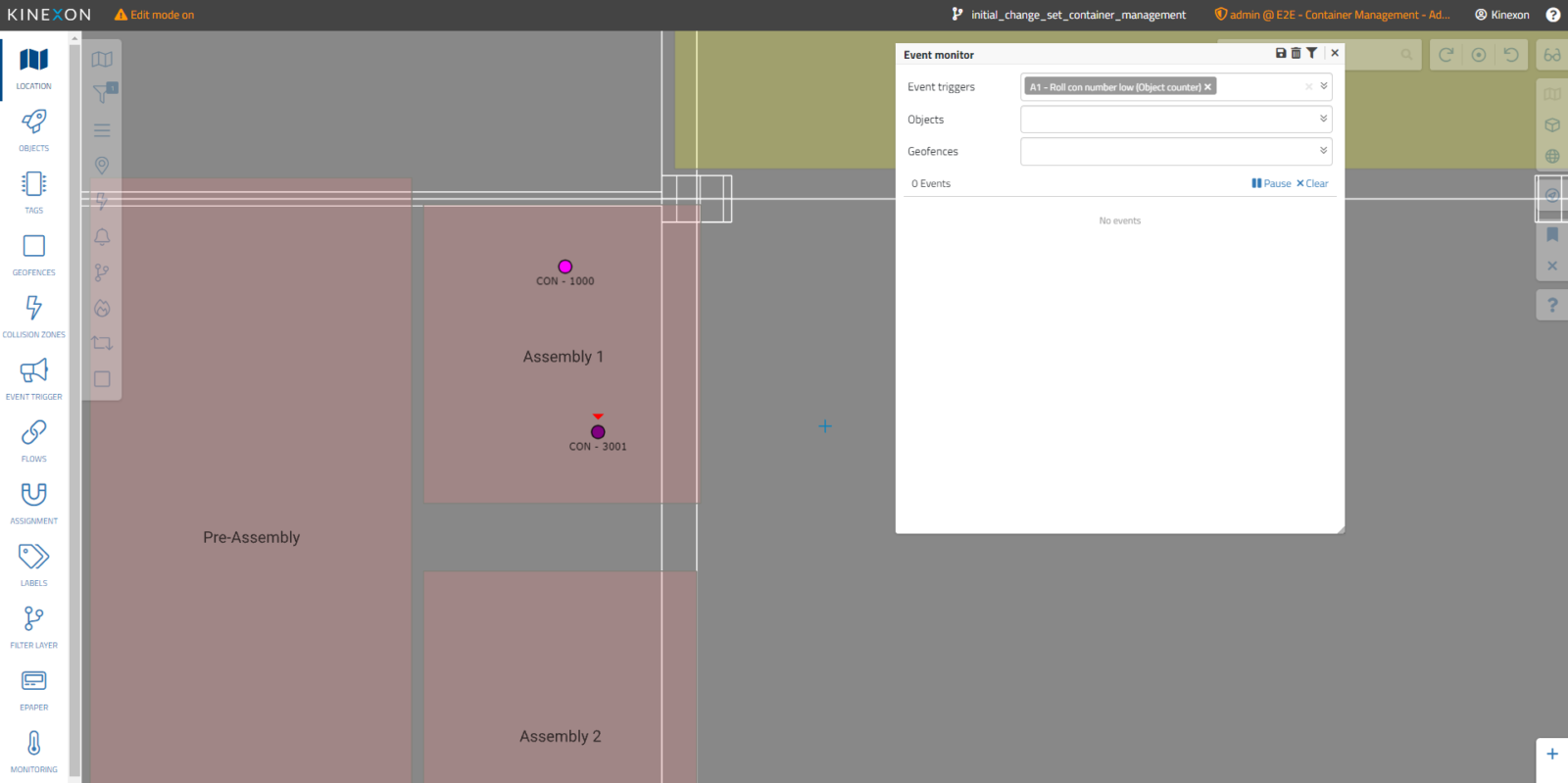

KINEXON attaches indoor location tags to containers to generate their precise position data on the shopfloor through Real-time Locating Systems (RTLS). Our Location-based Process Automation (LPA) software KINEXON OS turns your shopfloor into a powerful digital twin that enables you to automate and optimize processes through the interaction of location data, geofences, and event triggers.

How to gain a competitive advantage with automated container management?

KINEXON is a global technology leader in full-stack industrial IoT solutions. Our agile and scalable software KINEXON OS automates industrial processes through indoor location data from technologies such as BLE, UWB, or RFID. This enables leading customers in industries such as automotive, aerospace & defense, and discrete manufacturing to cut costs, increase cycle speed, and optimize documentation in production-critical processes. Automating container management adds value from day one and can be scaled into unlimited process automation use cases.

KINEXON RTLS

The indoor location system KINEXON RTLS enables full visibility of container movements and status in real time.

KINEXON OS

KINEXON OS is your central software to automate and optimize container movements and utilization via indoor location data.

UWB Technology

Ultra-wideband (UWB) technology is the gold standard for indoor localization via RTLS with up to 10cm positioning accuracy.

More about UWB