Order Tracking and Process Management

Automated Order Tracking and Process Management for Smarter Manufacturing

Did you know you can leverage real-time location data from connected assets to drive smarter operations through use cases such as automated order management, quality control, or material replenishment? Automating industrial processes that involve large numbers of moving assets eliminates error-prone and time-intensive manual tasks and increases overall operational efficiency.

Automated Order Tracking & Process Management: Streamline, Automate, Improve. Get Your Business Moving!

Watch our webinar and

- Discover the full benefits of automated order tracking and process management

- Understand how using location data for process automation can help save time, money, and resources

- See the live application of automated order management, quality control, and material replenishment

Get ready to digitize assembly workflows and reduce manual tasks

Discover how KINEXON + SAP provides real-time transparency on order tracking and process management.

How does automated order tracking and process management automation solve key challenges in manufacturing?

Order tracking and process management automation are important solutions to cut cost while increasing throughput in today’s competitive manufacturing environment. By leveraging real-time location data, they create greater transparency and optimization opportunities for a variety of profitable use cases throughout industrial production. By eliminating search times, repetitive manual tasks, and low utilization rates, automated order tracking and process management cuts down non-productive work time as well as transportation and inventory cost. In addition, it significantly increases product and process quality.

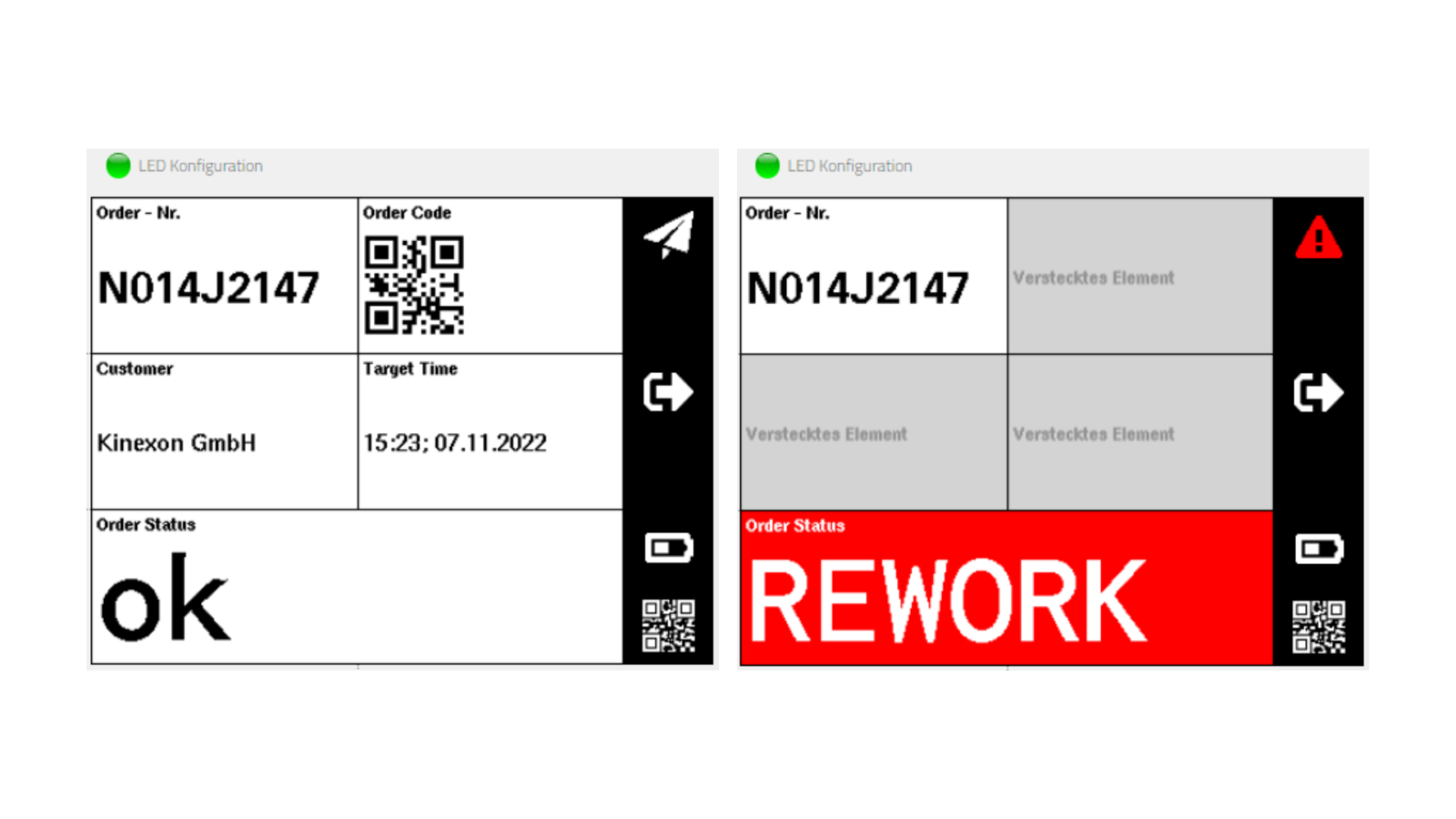

Automated Order Tracking

Automated order tracking optimizes order monitoring, reporting, and claim management in industrial operations. Automated order tracking creates fully visible order control and eliminates process bottlenecks such as overruns in buffer zones.

Automated Quality Control

Automated quality control enables significant quality improvements across production processes. It ensures compliance with process regulations such as acclimatization times or storage principles and uncovers process violations early before they result in costly rework or scrap.

Automated Material Replenishment

Automated material replenishment provides manufacturers with full transparency about the status and location of materials. It enables companies to preemptively detect material demands and automatically trigger replenishment processes, which optimizes resource utilization and inventory control.

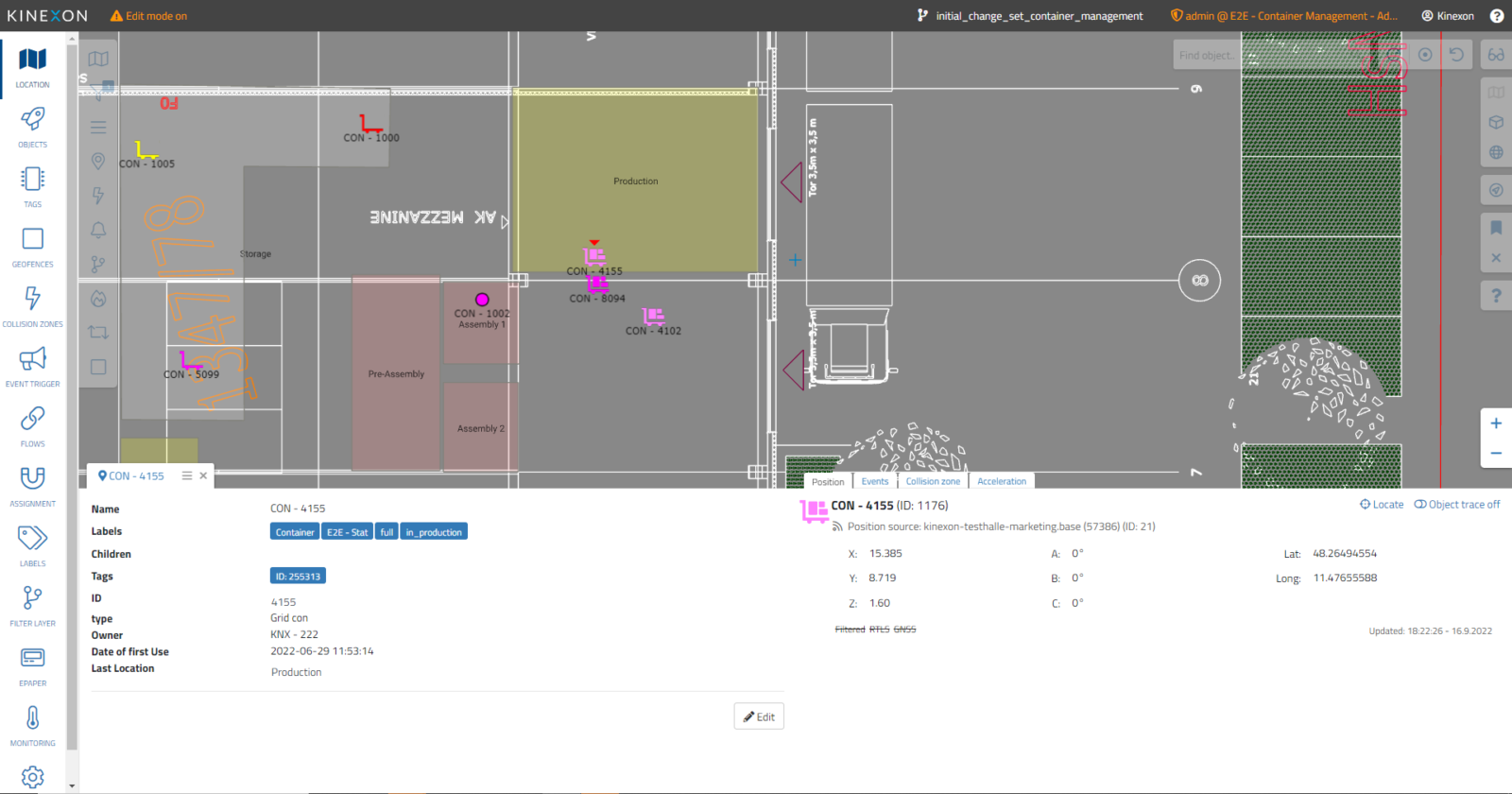

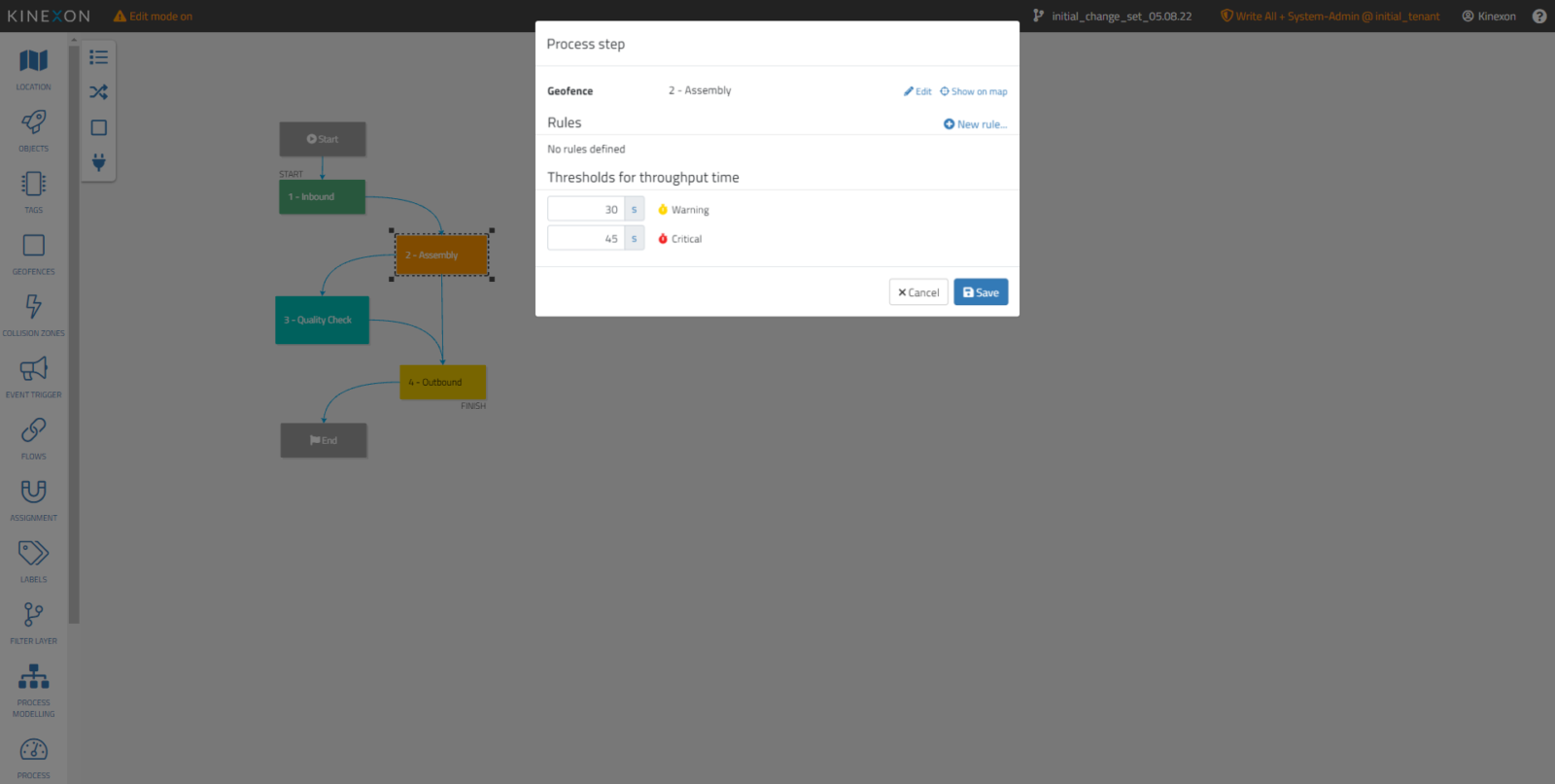

How order tracking and process management work with KINEXON OS and RTLS

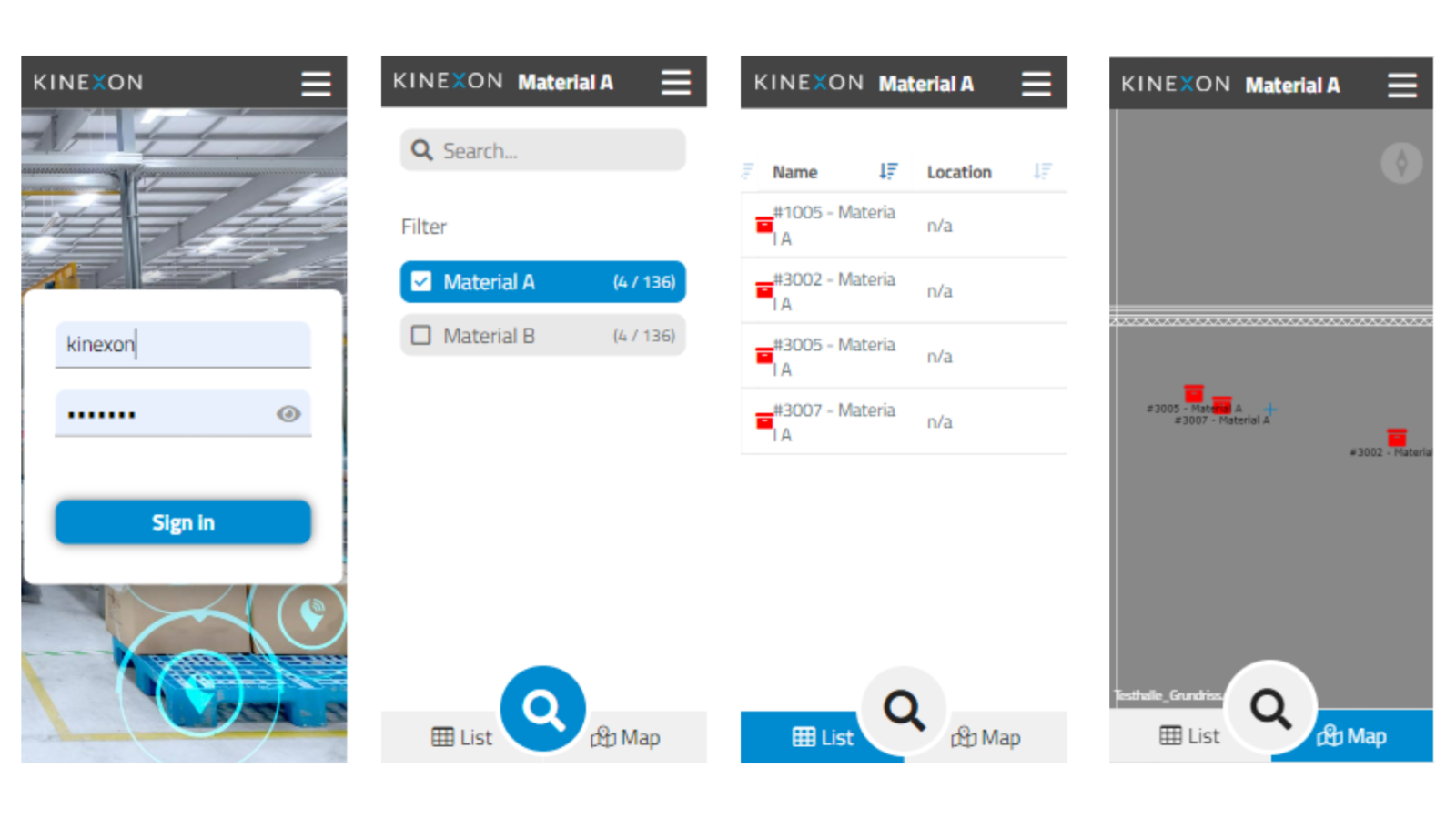

We leverage indoor location technologies to generate precise position data of moving assets on the shopfloor with our KINEXON UWB RTLS as well as BLE and RFID. Our Location-based Process Automation (LPA) software KINEXON OS turns your shopfloor into a powerful digital twin that enables you to automate and optimize processes through the interaction of location data, geofences, and event triggers.

How to gain a competitive advantage with automated order tracking & process management

KINEXON is a global technology leader in full-stack IoT solutions for location-based process automation (LPA). Our agile and scalable LPA software KINEXON OS enables leading customers in manufacturing to cut costs, increase cycle speed, and optimize quality in production-critical processes. It is our mission to add value in unlimited use cases for our customers from day one.

KINEXON RTLS

Our indoor location system KINEXON RTLS generates precise location data for moving assets in real time and enables full visibility of intralogistics and production processes.

KINEXON OS

KINEXON OS is your central software to automate and optimize operations processes via indoor location data from technologies such as UWB, BLE, or RFID.

UWB Technology

Ultra-wideband (UWB) technology is the gold standard for indoor localization via RTLS with up to 10cm positioning accuracy and unparalleled transmission speed.

More about UWB