AMR & AGV Fleet Management

Optimize AMR & AGV Operations with KINEXON Fleet Management

Due to significant labor shortages and cost increases companies face the need to expand their automation system on their factory and logistic shop floor.

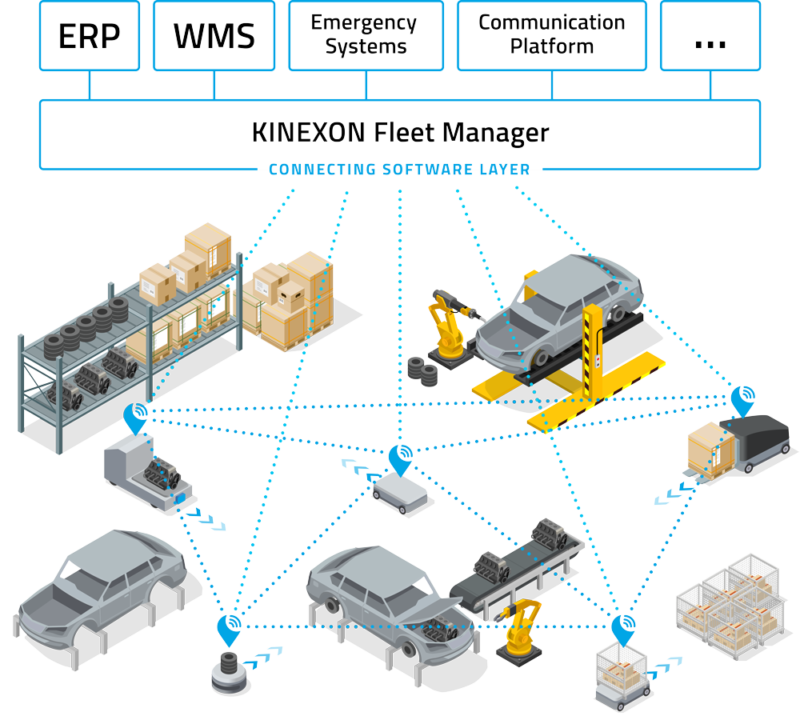

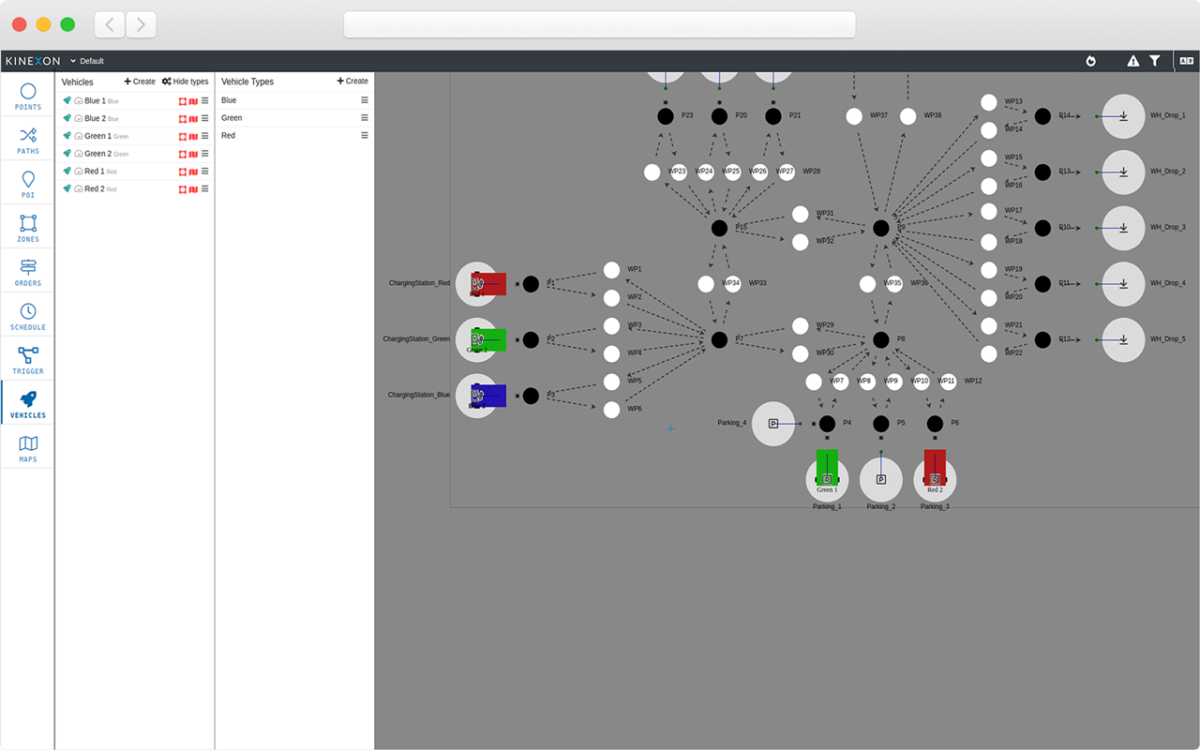

Our solution offers a control tower for the effective, real-time coordination of AMR fleet operations with single or multiple vehicle types on the shop floor. It works vendor-independently and supports industry standards, such as the VDA5050.

The open architecture and modern user interface ensures flexible management of all sorts of vehicles and optimal material flow.

Download our one-pager and get an overview of the KINEXON AMR & AGV Fleet Management Software.

Say hello to future-proof fleet orchestration

Discover how KINEXON + SAP provide lean interactions through standard interfaces to unify diverse fleets and simplify implementation, operations and maintenance.

Unlock the Power of Autonomous Mobile Robots

AGV stands for Automated Guided Vehicles. These floor-bound vehicles are used to transport materials and goods on the production shop floor. They are mostly navigated by means of physical track guidance aids, such as magnetic strips or something similar. The travel paths are often rigid, and need to be planned before the system setup and any updates or changes are very time-consuming and expensive.

The next level of automated vehicles are so called Autonomous Mobile Robots: they are considered autonomous, as they freely move on the shop floor. No physical guidance is required, as they are coordinated through a central control tower, making the use of AMRs effective, trackable, real-time and easy to maintain or upgrade.

When using a vendor-independent and hardware-agnostic fleet manager, entire fleets of AGVs and AMRs — with single or multiple vehicle types — can freely navigate side-by-side with workers or other vehicles, leading to much higher flexibility.

Intelligent fleet management and control software leverages the power of more autonomous mobile robots.

Orchestrate AMRs and AGVs Vendor-Independently

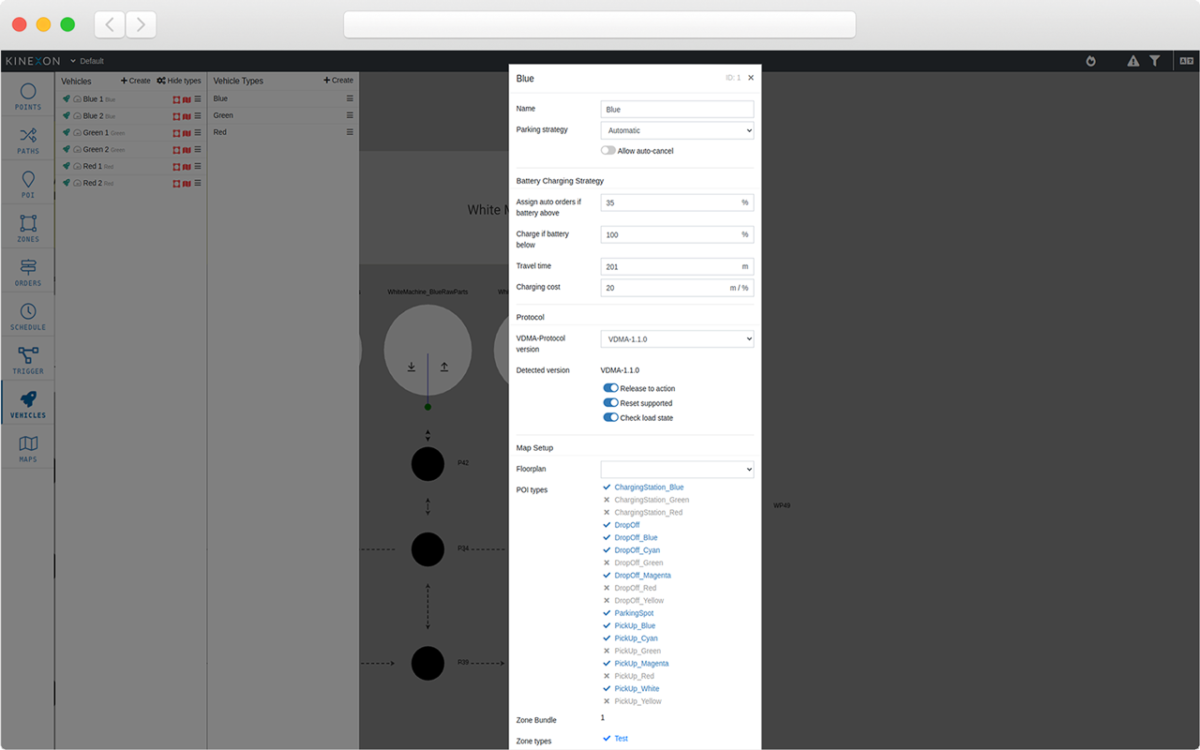

We empower you to operate your preferred robot type from your preferred manufacturer. That’s why we chose a VDA5050-compliant and vendor-agnostic approach which allows you to combine multiple vehicles and interfaces on the same shopfloor.

Increase Productivity and Extend Automation

Select the best robot type for each use case in your system. Based on factors such as the current charging status, real-time traffic information or the distance to the next charging station, the fleet manager optimizes the availability of the robot fleet in real-time.

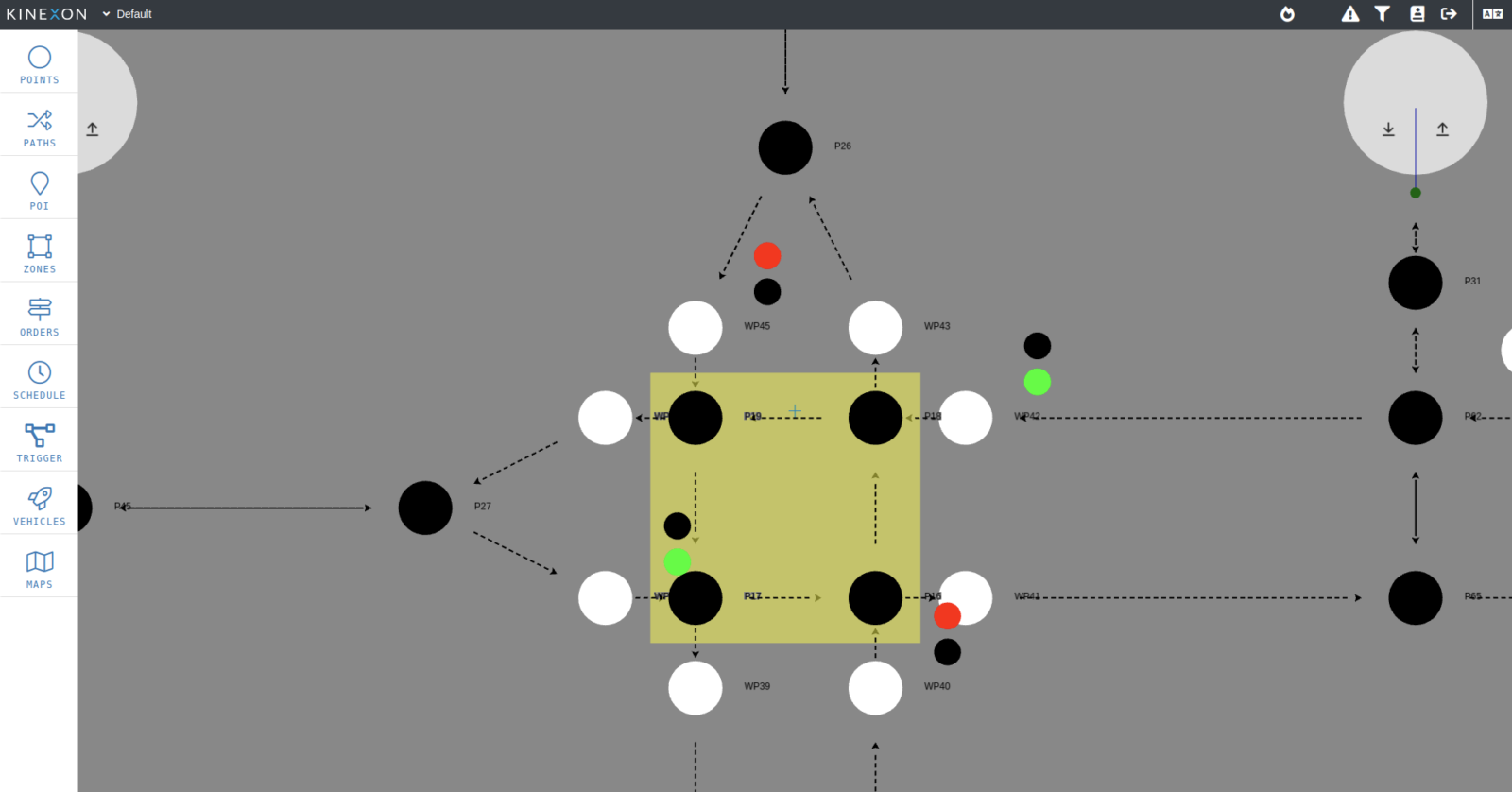

Optimize Material Flow and Increase Safety

Multiple zone types enable real-time traffic management, based on individual rules. Restriction zones and fire-alarm zones increase workers safety and enable a secure environment.

Increase Overall Equipment Effectiveness Through Maximum Robot Availability

The fleet management software optimizes the availability of the robot fleet based on factors such as the current charging status, distance to the next charging station and traffic.

Facts and Figures

KINEXON x Continental: Staplerworld Reports about the Strategic Partnership

Kinexon and Continental partner up and achieved significant milestones on the path to the factory of the future. The KINEXON AMR & AGV Fleet Manager and Continental’s Autonomous Mobile Robots are integrating and interacting seamlessly through the VDA 5050 interface. Together, they’ve optimized operations across multiple sites, achieving over 99.98% availability of the system. This dynamic partnership is transforming the landscape of smart manufacturing.

See It Live and in Action at Our Experience Center

Experience our KINEXON AMR & AGV Fleetmanagement Software live.

More information about our IoT Experience Center