Tool Control

Increase Assembly Speed with Automated Tool Control

Complex assembly processes have a high potential for error, which can be a major challenge for manufacturers in a competitive global environment. Automated tool control solves this challenge by eliminating manual work steps by leveraging ultra-precise location data. Through geofencing, preset tool configurations, and continuous digital documentation, automated tool control reliably increases process quality, productivity, and flexibility.

How does automated tool control solve key challenges in the automotive industry?

Companies in the automotive industry are facing enormous pressure today: a trend towards batch size 1 production with more customer-customized requirements, ever-increasing product quality and safety expectations, as well as a uniquely competitive industry landscape. This creates the need for OEMs to implement smart automated tool control. By automating manual steps in tightening operations, automated tool control ensures superior speed and quality control along complex mixed-model assembly line systems.

Why should you automate your assembly with KINEXON tool control?

Increasing quality and speed of assembly processes with automated tool control

The value and benefits of automated tool control

Implementing efficient tool control with KINEXON

How does KINEXON tool control automation via KINEXON OS and RTLS work?

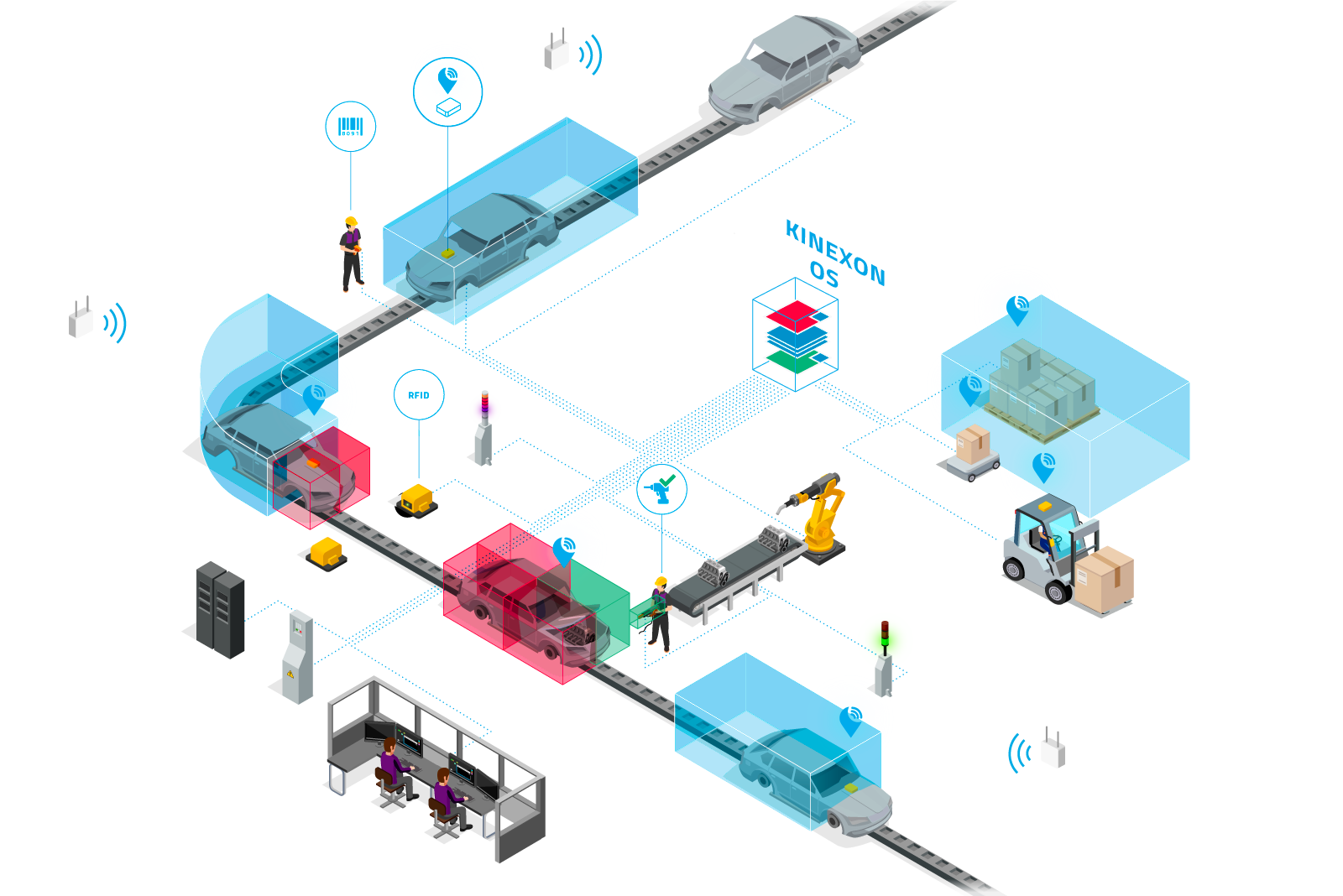

Data from UWB RTLS sensor-equipped parts and tools interacts with geofences, event-based triggers, and more in our Location-based Process Automation software KINEXON OS. As a product moves through a predefined zone, each necessary tool is activated, and the proper settings are configured per the individual requirements. Fast and easy setup and installation ensure efficient scalability — even in the most complex automotive assembly lines.

Your competitive advantage with KINEXON: Ultimate scalability for unparalleled process automation

Automated tool control increases assembly speed and production quality. KINEXON’s automation solutions expand much beyond assembly tools. Explore how our central software solution grants you the ultimate competitive advantage by automating and optimizing your entire production: