KINEXON Operating System

Move Beyond Your IoT Blind Spot with Location-based Process Automation

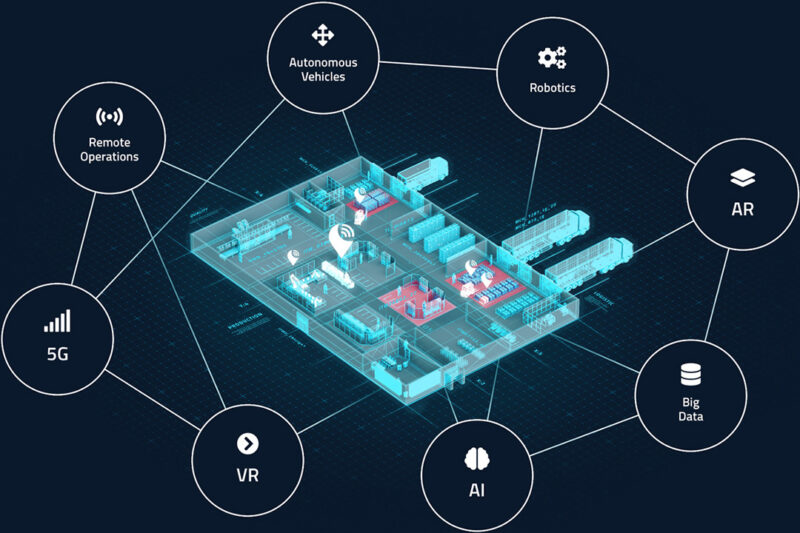

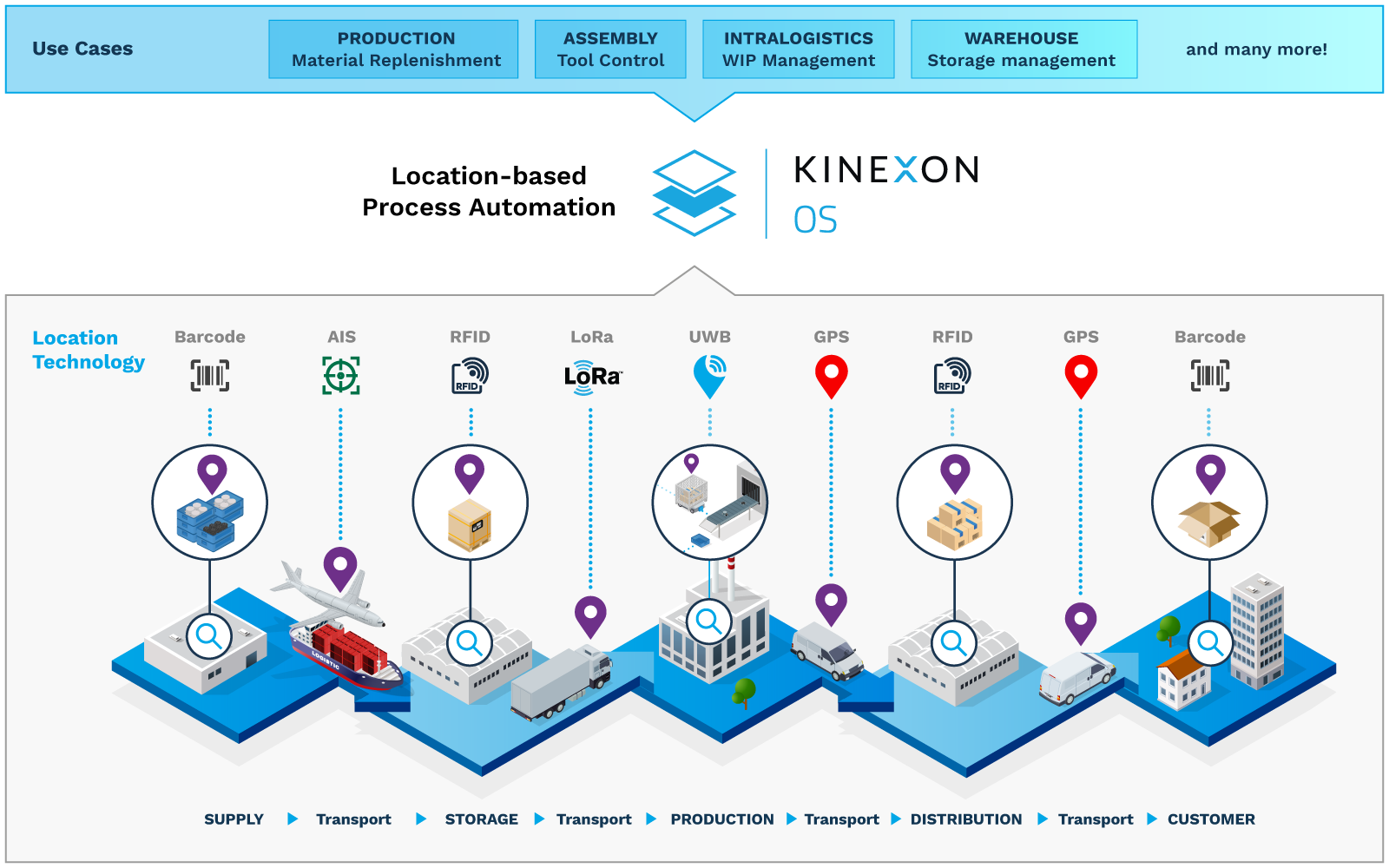

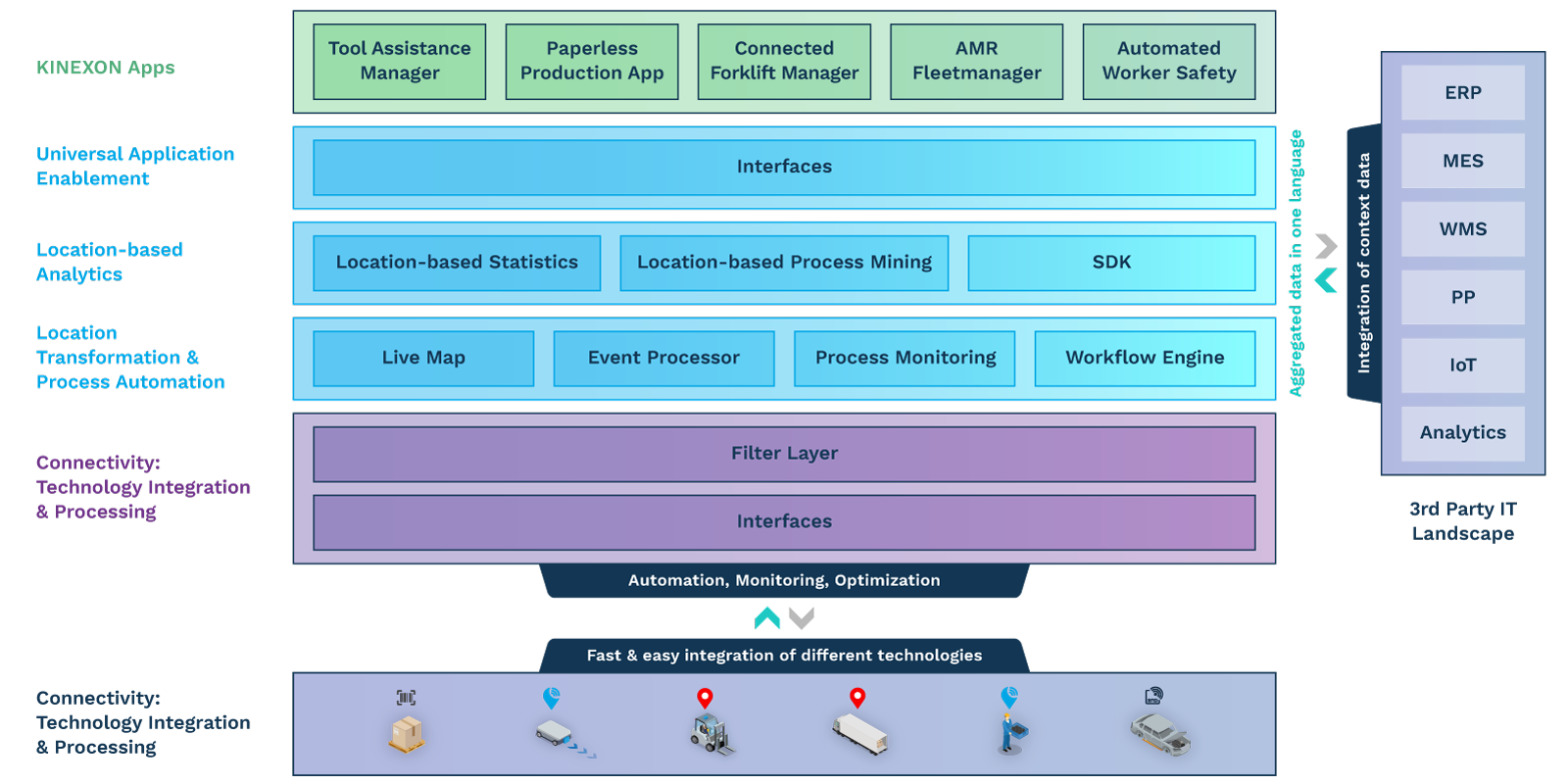

Location-based process automation (LPA) is the key enabler for autonomous operations. With KINEXON OS, we provide you with a powerful real-time operating system to analyze, optimize, and automate all processes via location technologies from BLE and UWB to GPS. Enabling virtually unlimited use cases, KINEXON OS adds direct value to your operations in real time and provides invaluable insights to future-proof your business.

DOWNLOAD WHITE PAPER

Ready for next-level operational efficiency?

Discover how KINEXON + SAP work together to orchestrate shopfloor operations and processes.

Customer Testimonial: BMW

“Thanks to the open technology […] we can connect new backend systems without having to program a special software interface each time beforehand. This makes it easier and faster than before to implement applications for improving manufacturing processes using location data.”

Thomas Strebin, Product Owner Ident & Locating at BMW

Whitepaper: Download Now

Your Location-based Process Automation insights: In this whitepaper, you will learn everything you need to know about how this new software category leverages location data for autonomous operations.

DOWNLOAD NOW

80% - The Amount of Enterprise Data Containing Location Components

Harness the power of this treasure trove of data to add value via process automation: a digital twin of all moving assets allows you to monitor your operational KPIs in real time and optimize your production and warehousing operations. Start leveraging location data and join the 79% of executives who are scaling smart automation and believe they will outperform their competition in revenue growth within the next 3 years.

New Software Category Enables Unprecedented Use Cases and Benefits

The Location-based Process Automation software KINEXON OS offers you unlimited apps for the end-to-end automation of your production and logistics.

KINEXON OS Consolidates Data and Technology Silos

Interoperability is a key factor for your automation strategy: KINEXON OS is designed to break up data and technology silos and integrate data from all location technologies — from BLE to UWB and GPS. Our open software eliminates costly middleware and allows you to centrally automate along your entire supply chain, from anywhere in the world.

Enabling OT: Seamless Integration, Simple Implementation

Minimum IT effort for maximum OT value: KINEXON OS is your next generation software solution for autonomous operations. OT employees are empowered to implement and customize any automation use cases — in a simple low code/no code environment. The data and insights won seamlessly fuel third-party systems, from MES to WMS and ERP.

"Our low code / no code approach ...

… enables production and logistics managers to create new use cases on their own, per simple drag & drop. This allows our clients to leverage the full potential of industrial automation as a whole and each OT employee. In light of the global lack of IT talent, this is a decisive advantage of KINEXON OS.”

Dr. Oliver Trinchera, Co-Founder & CEO, KINEXON

Your Smart Process Automation System: Key Features Overview

KINEXON OS offers you the following features to kickstart your automation journey:

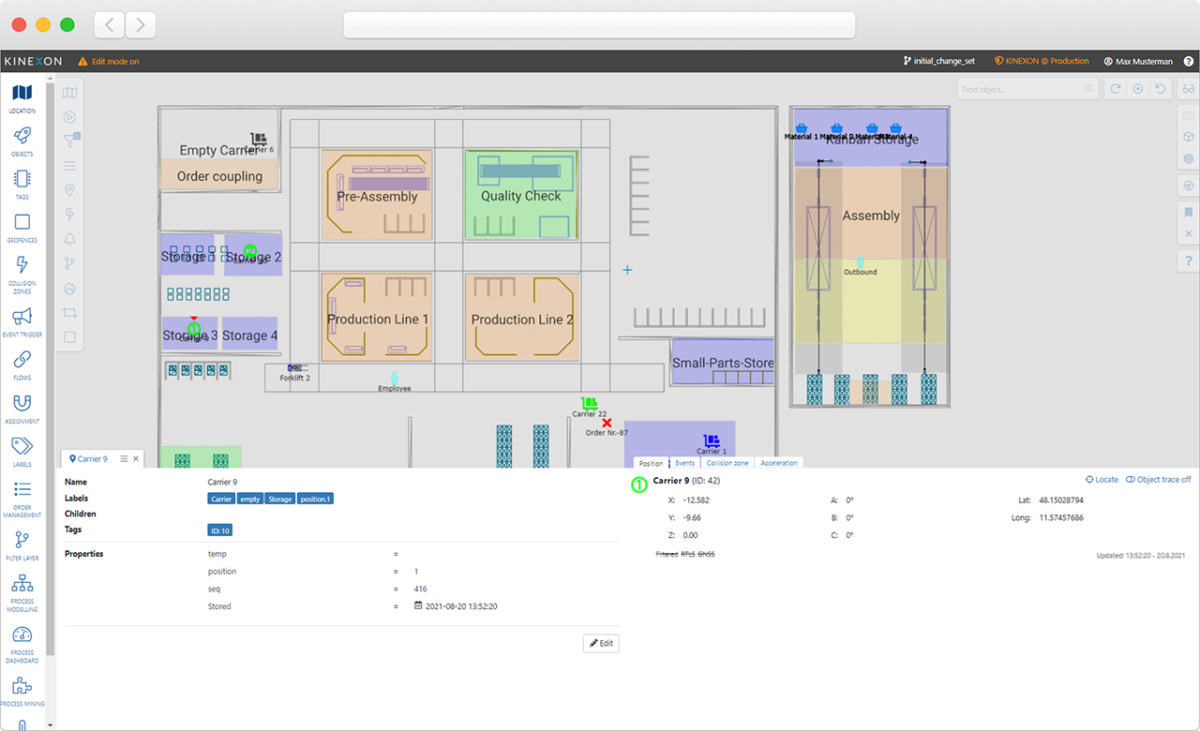

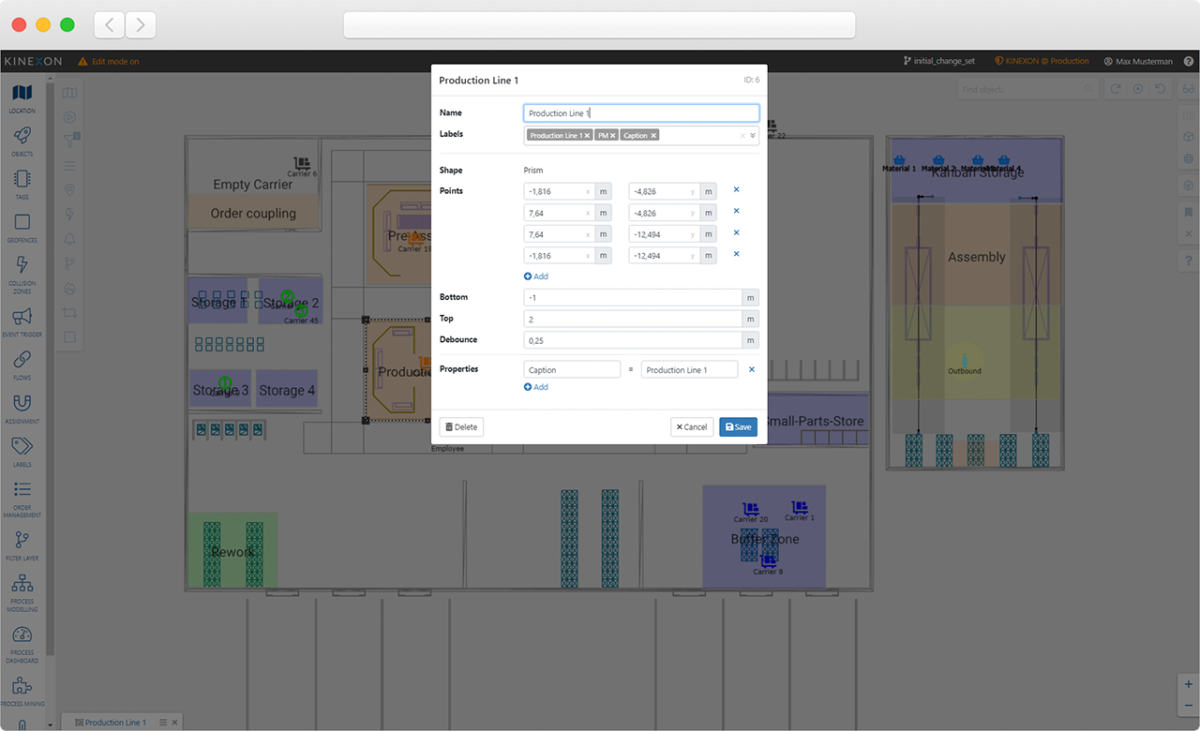

Digital Twin

The Digital Twin is a real-time visualization of all dynamic processes in your operations. Keep all movements on your shop floor in sight — via 2D or 3D visualization.

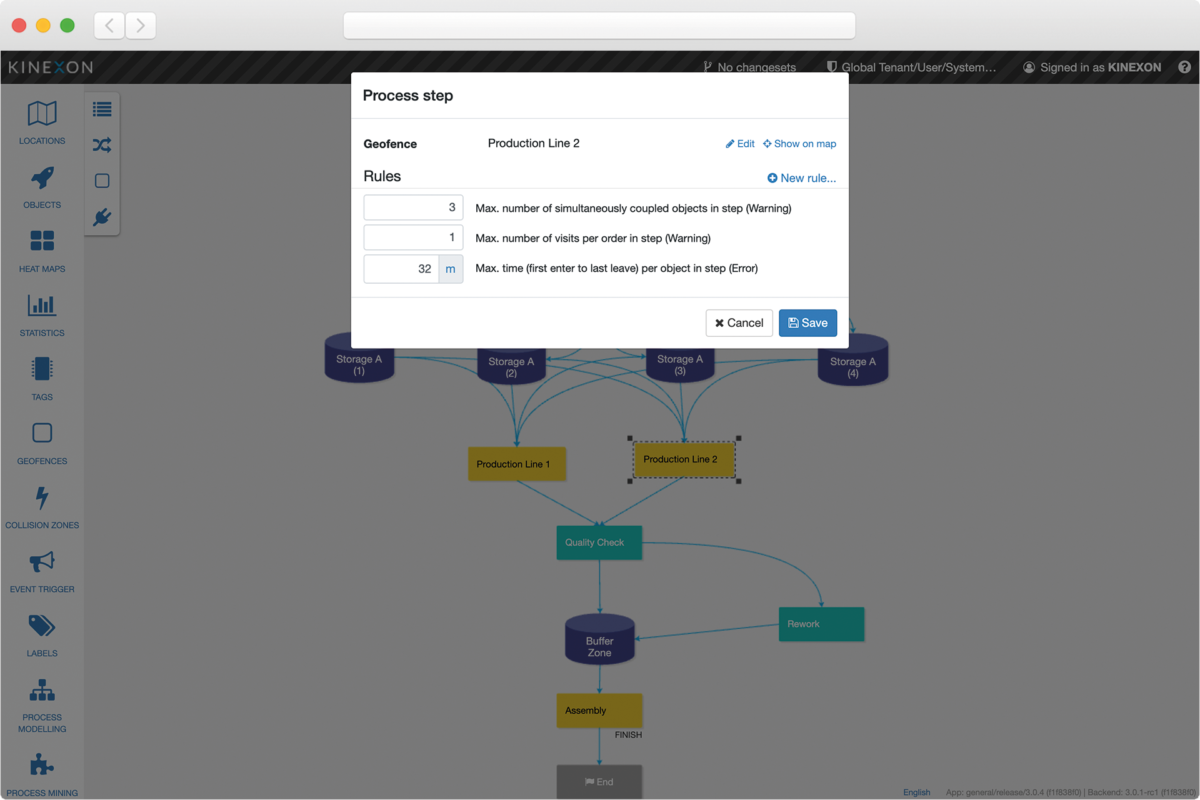

Process Automation

KINEXON OS allows OT users to automate and flexibly adapt logistics and production processes — without any IT involvement.

Real-time Process Monitoring

The intuitive interface allows users to centrally monitor their optimized production processes and to identify deviations in real time.

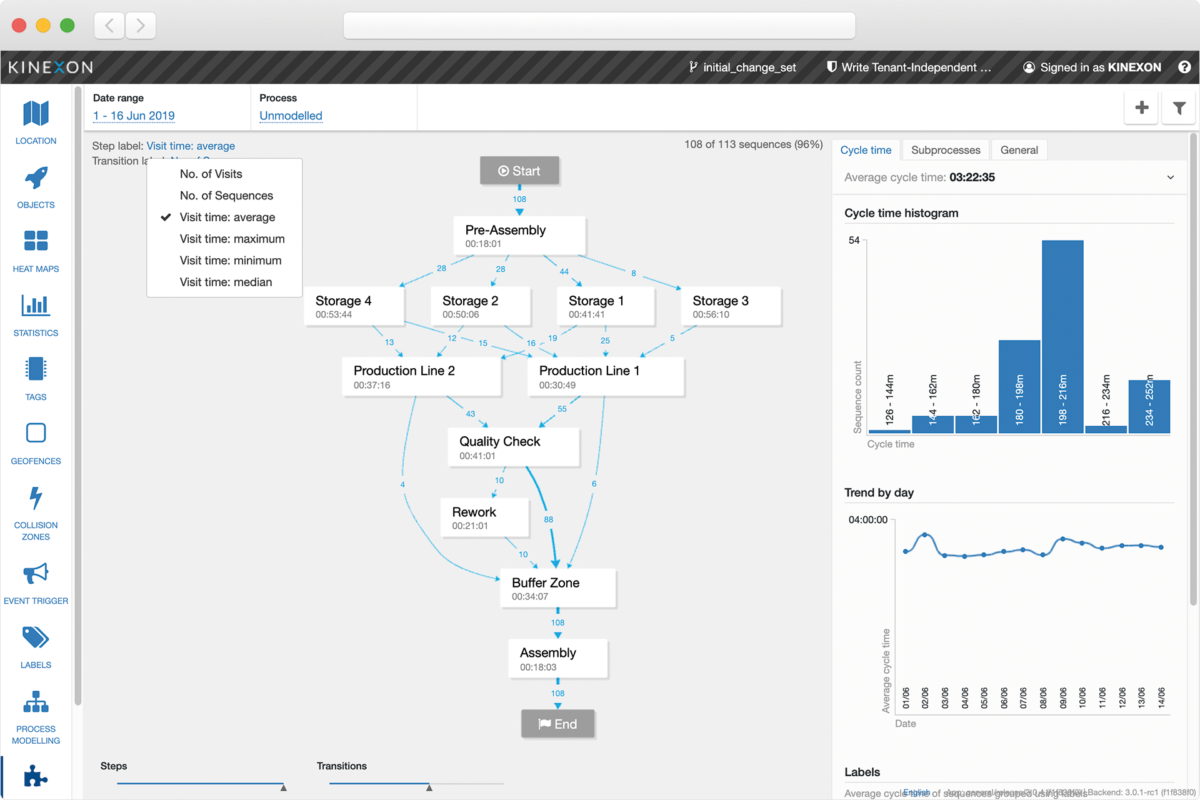

Process Mining

Process Mining generates insights on systemic weaknesses, process deviations, or material flow blind spots. The software helps users to model, monitor and mine processes across the entire production.

Download our Product Brochure

Take an in-depth look at the features and the use cases for KINEXON OS, and learn how you can seamlessly integrate it into your existing technology stack.

Future-Proof your Business with Location-based Process Automation

KINEXON OS leverages state-of-the-art technology for invaluable predictive analyses — providing value today and tomorrow. The software is also a key tool to leverage upcoming technologies, such as robotics, AI, or 5G. Additionally, KINEXON OS allows your employees to manage production and logistics processes remotely, setting your company up for the future of work.