Full Transparency on the Shop Floor

Modern Sensor Technology as a Door Opener to Tomorrow's Smart Factory

KINEXON SafeZone has shown that the latest sensor technology is an effective tool in times of COVID-19 to protect employees and business operations in the best possible way. But taken a step further, it opens up further digitalization potential and unprecedented transparency for companies on their way to tomorrow’s smart factory — from material flow optimization and automation of manual processes to cost savings.

The automotive supplier Continental, for example, shows how this can look in practice.

Everything’s in Perfect Flow

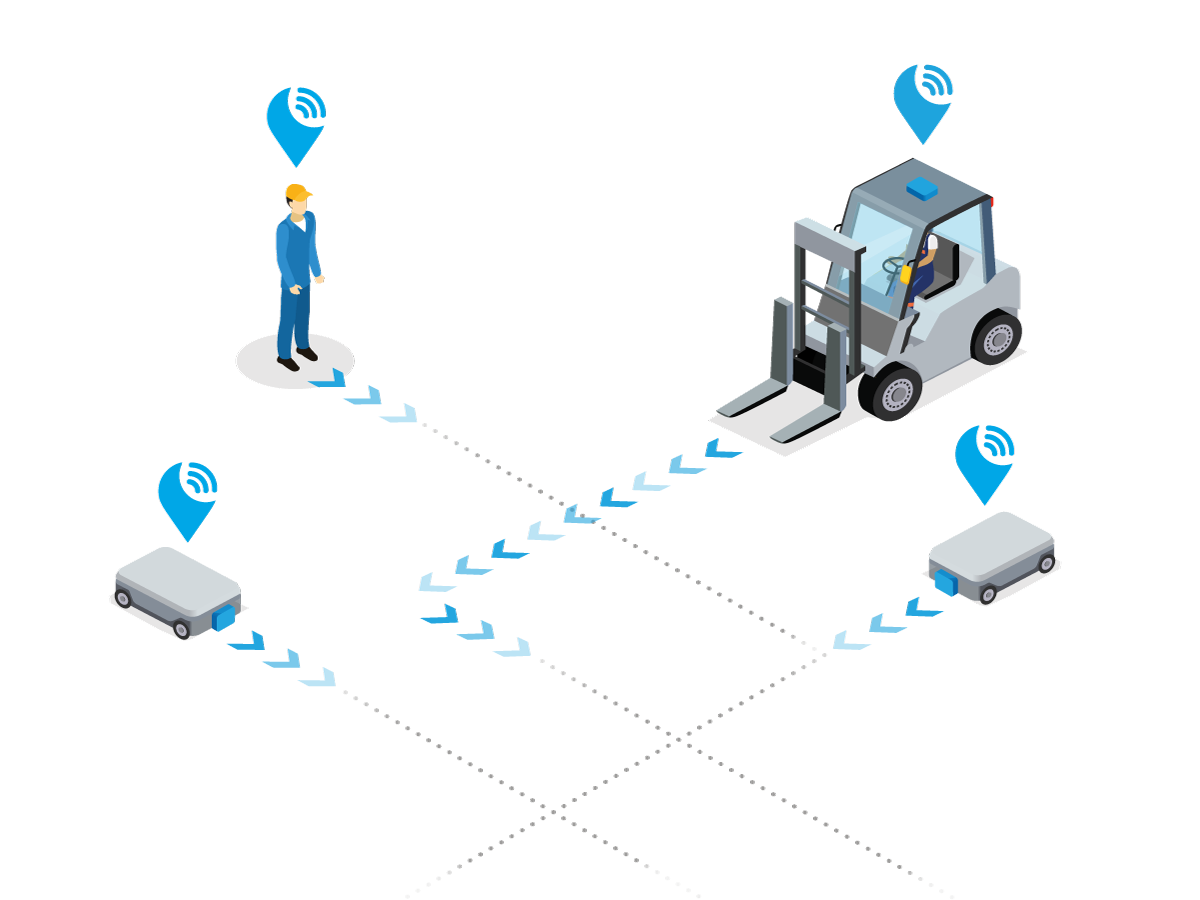

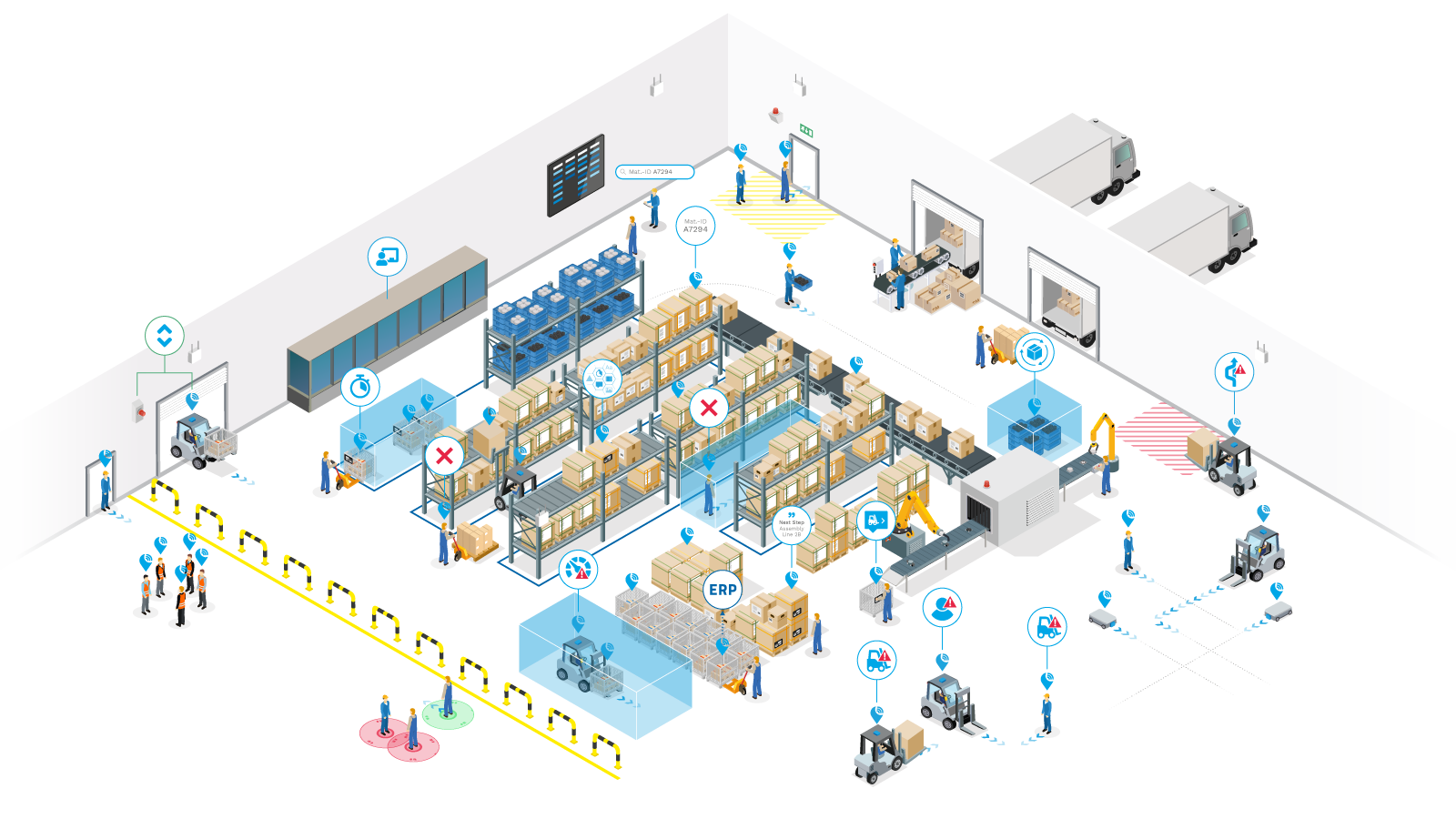

Whether human, machine or object — in the vision of the smart factory of tomorrow, all components are connected to each other and interact automatically in perfect flow.

KINEXON paves the way for companies and supports them by means of real-time localization, analytics and automation to digitalize what happens on their shop floor — all under the sign of full transparency. Real-time location intelligence enables the implementation of numerous use cases for…

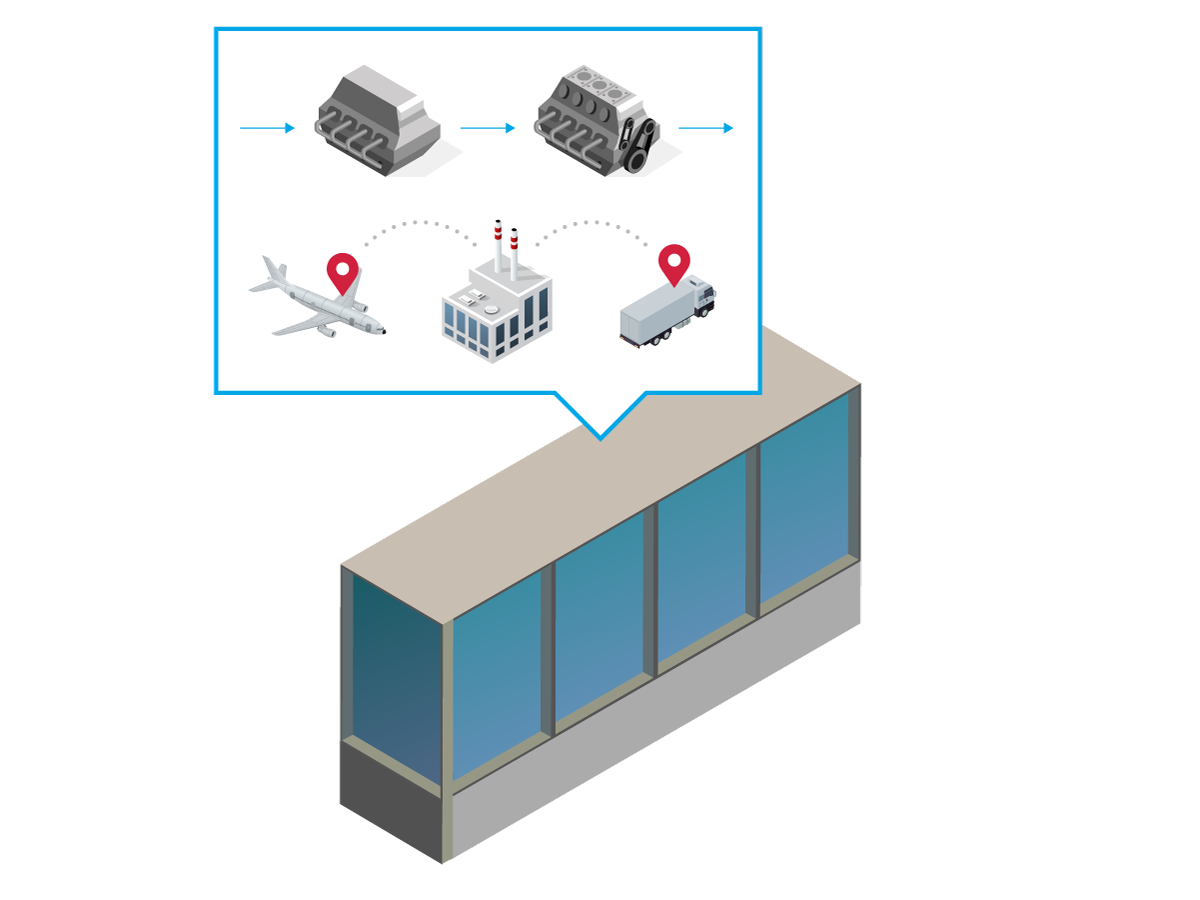

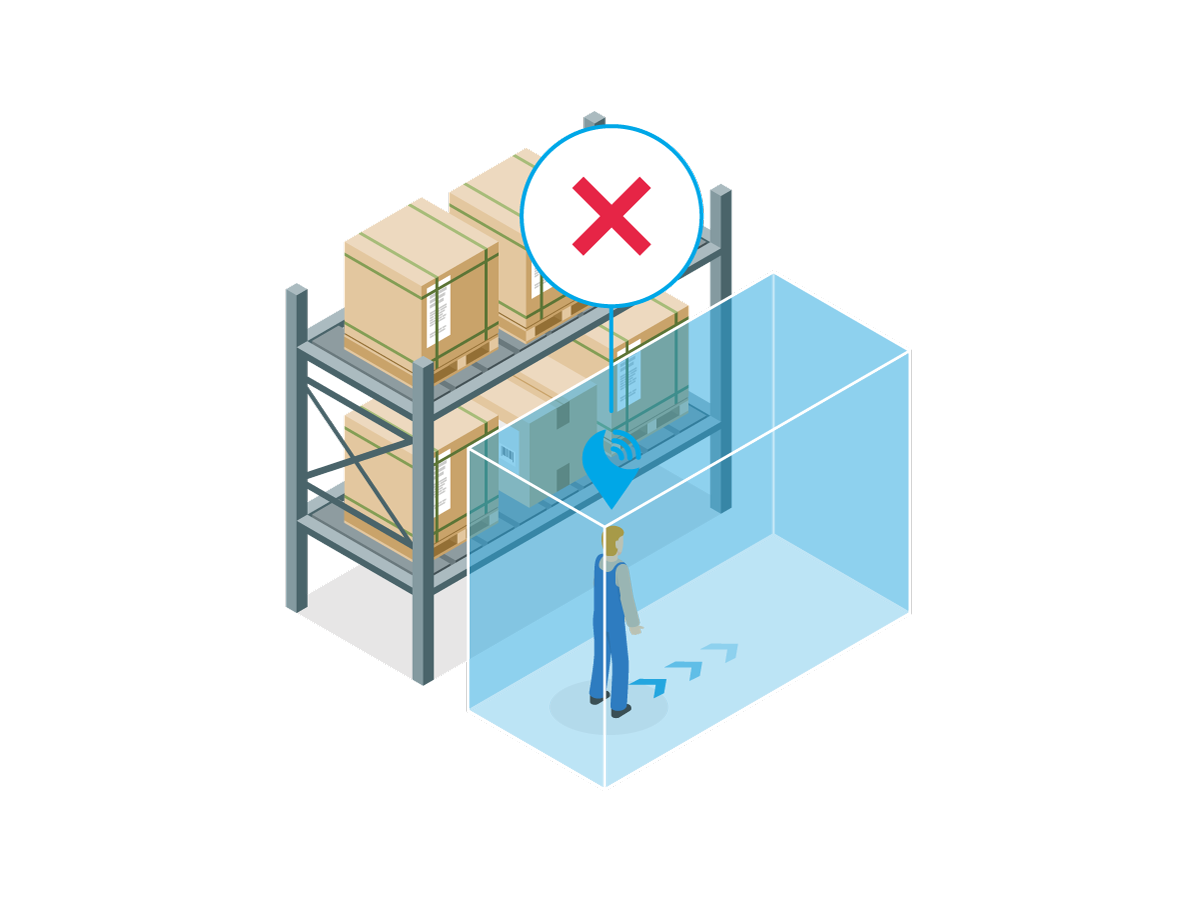

New Competitive Advantages With the Optimization and Automation of Material Flow

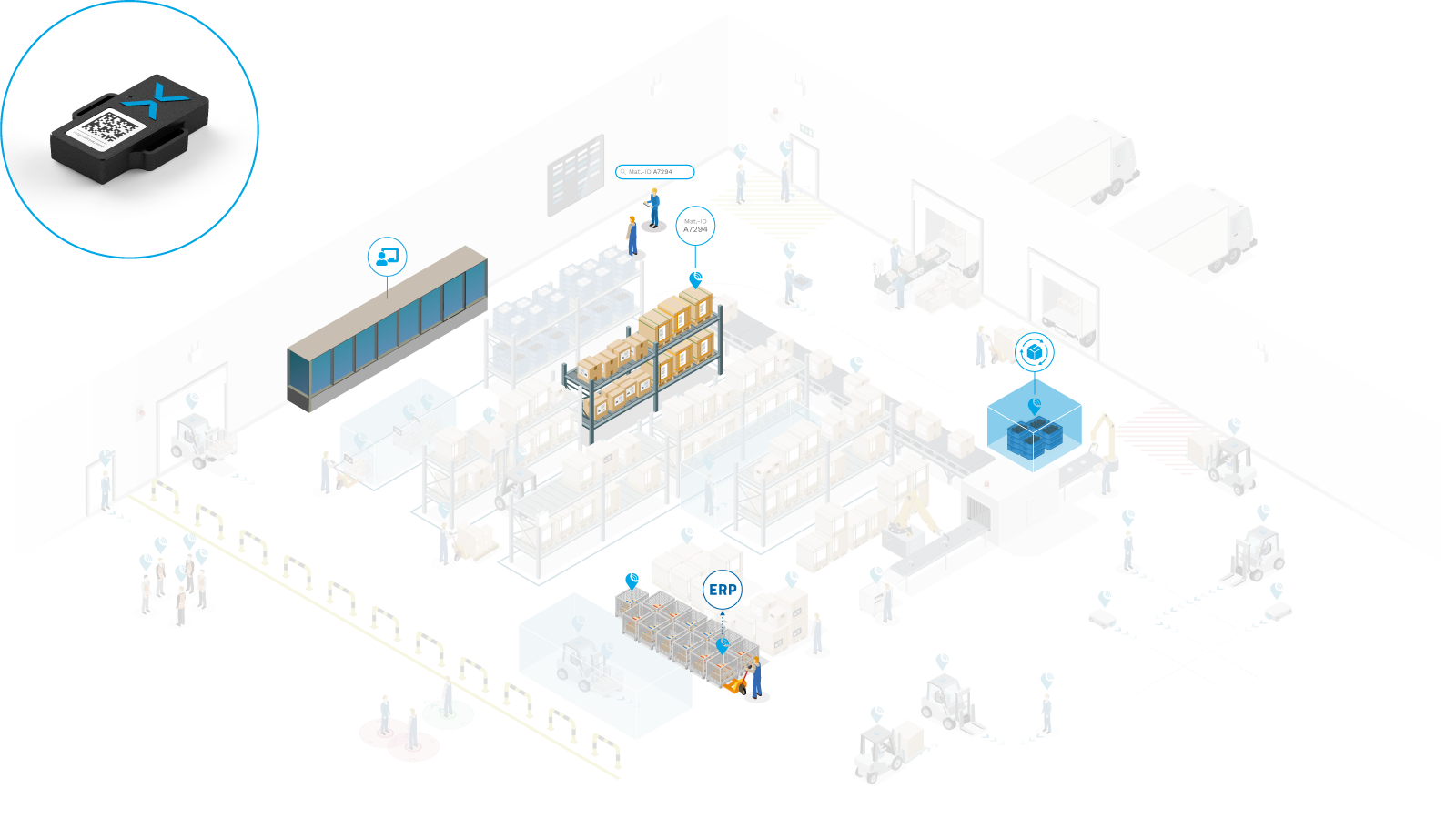

Accelerated throughput times, reduced material and warehousing costs and increased productivity are not only typical promises of tomorrow’s smart factory but can already be realized with the help of KINEXON RTLS including the world’s most cost-efficient UWB sensor, the KINEXON X‑Tag, and the location-based process automation software KINEXON OS.

EXPLORE THE X‑TAG

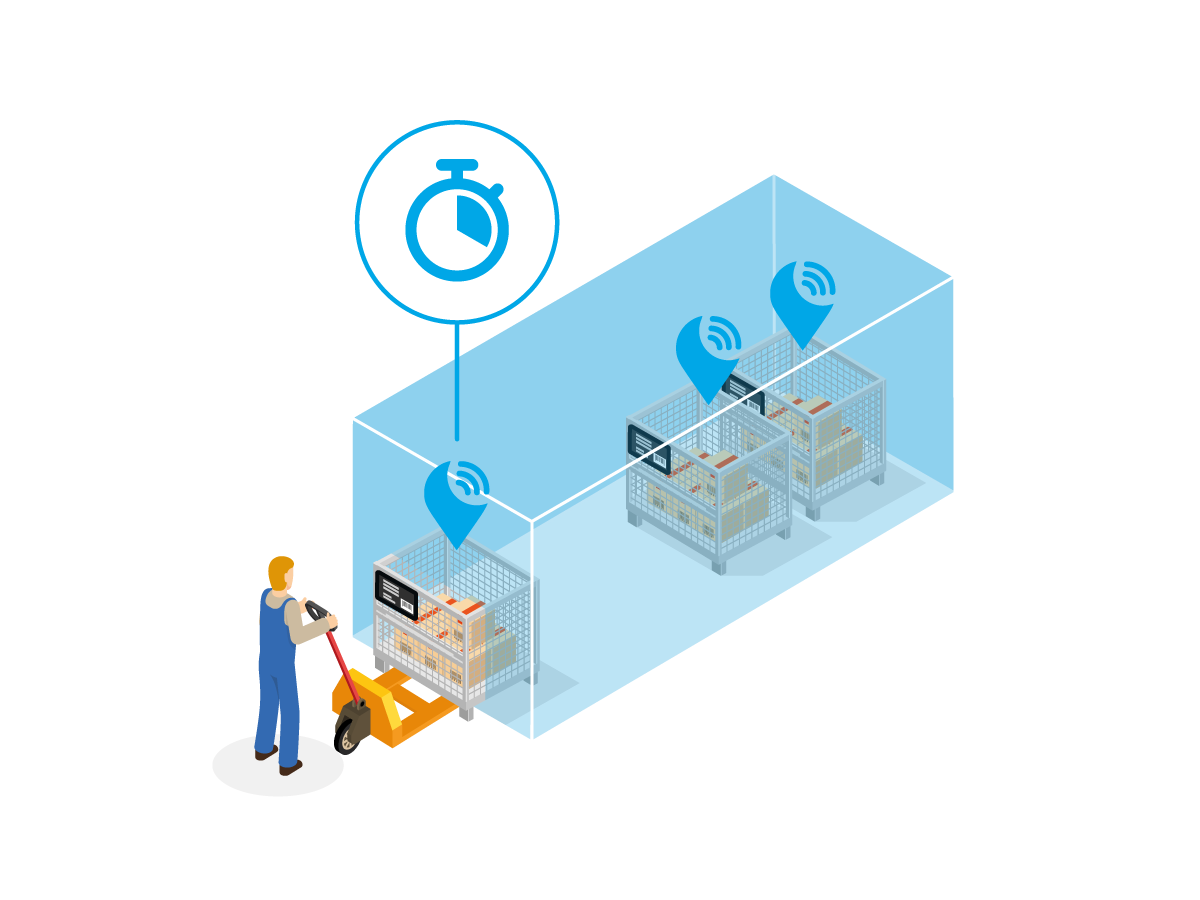

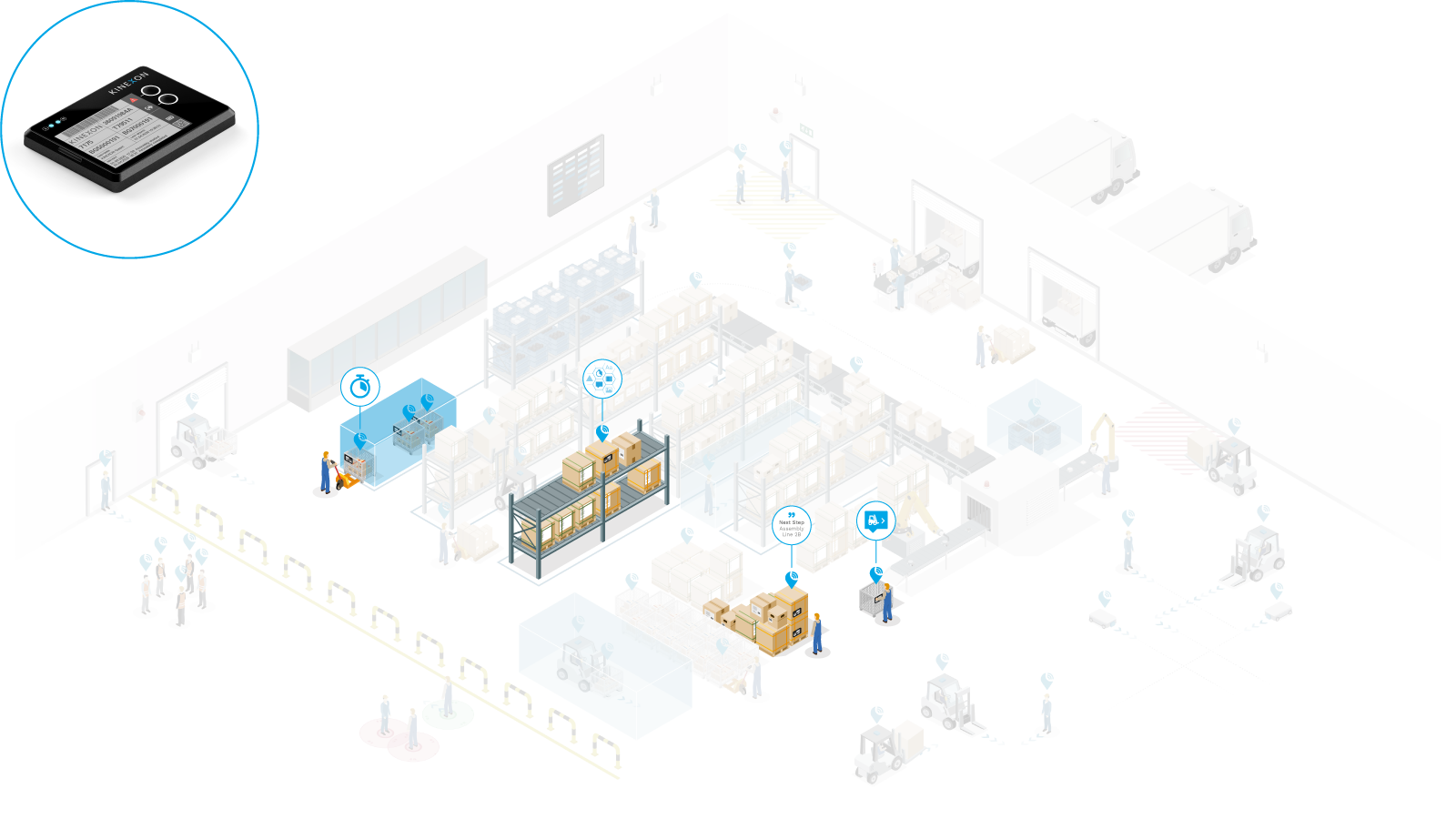

For More Efficiency and Sustainability: The Path to Paperless Production and Logistics

Combining ultra-precise UWB real-time localization and e‑Ink technology: KINEXON’s ePaper solution offers companies new possibilities for process visualization and digitization, all while reducing manual errors and paper usage. The result: more efficiency in production and order processes.

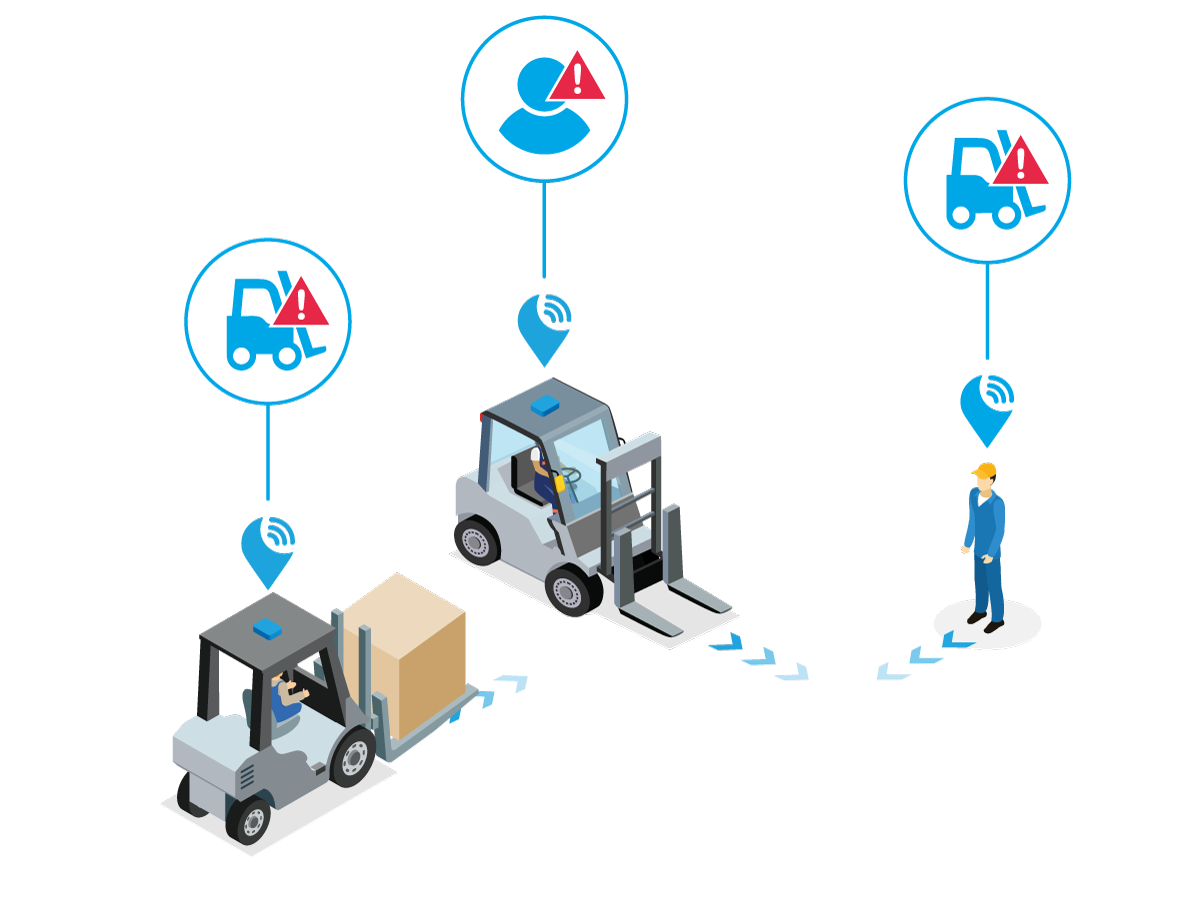

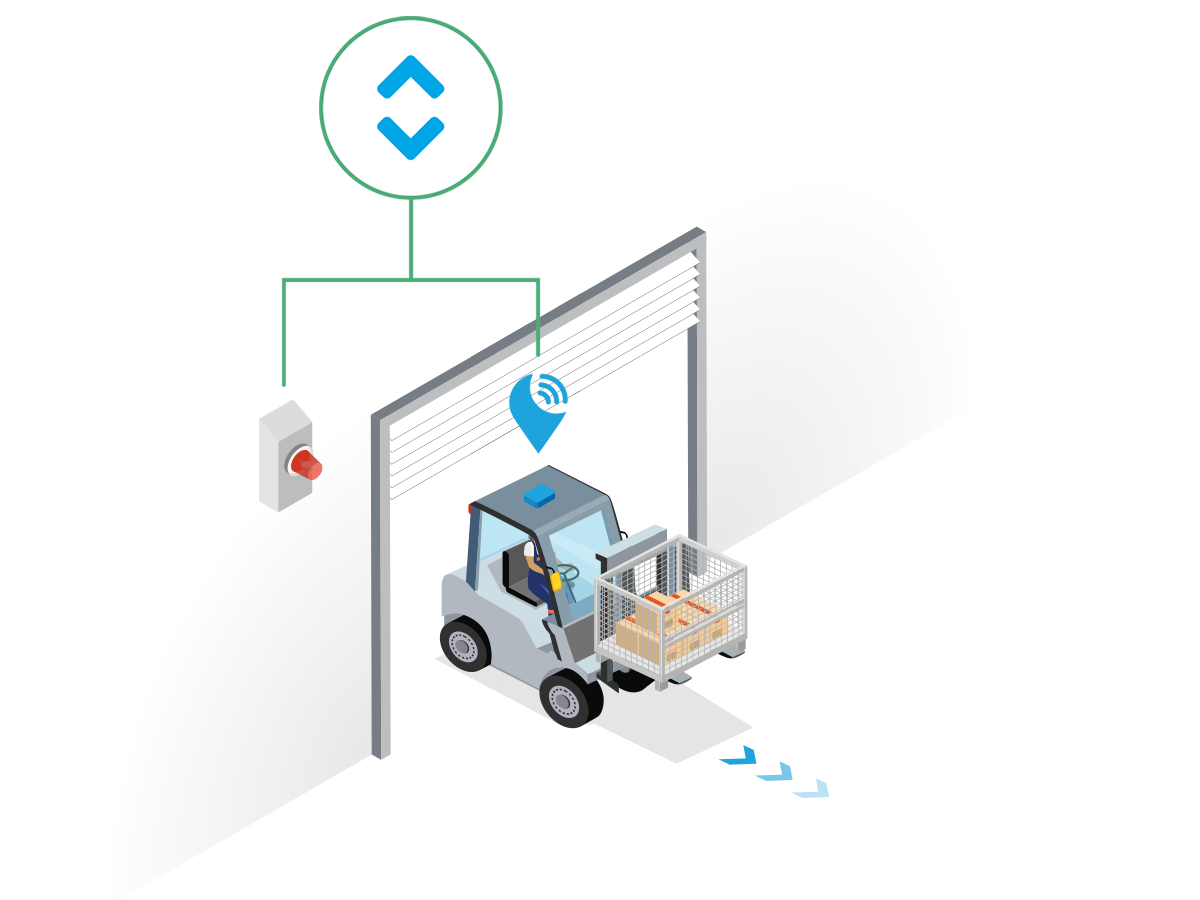

More Efficiency and Protection With Vehicle Tracking

Whether companies want to efficiently plan and check the routes of forklift trucks or protect their employees from collisions — with modern solutions for real-time localization, they always have the movements of their vehicles in view

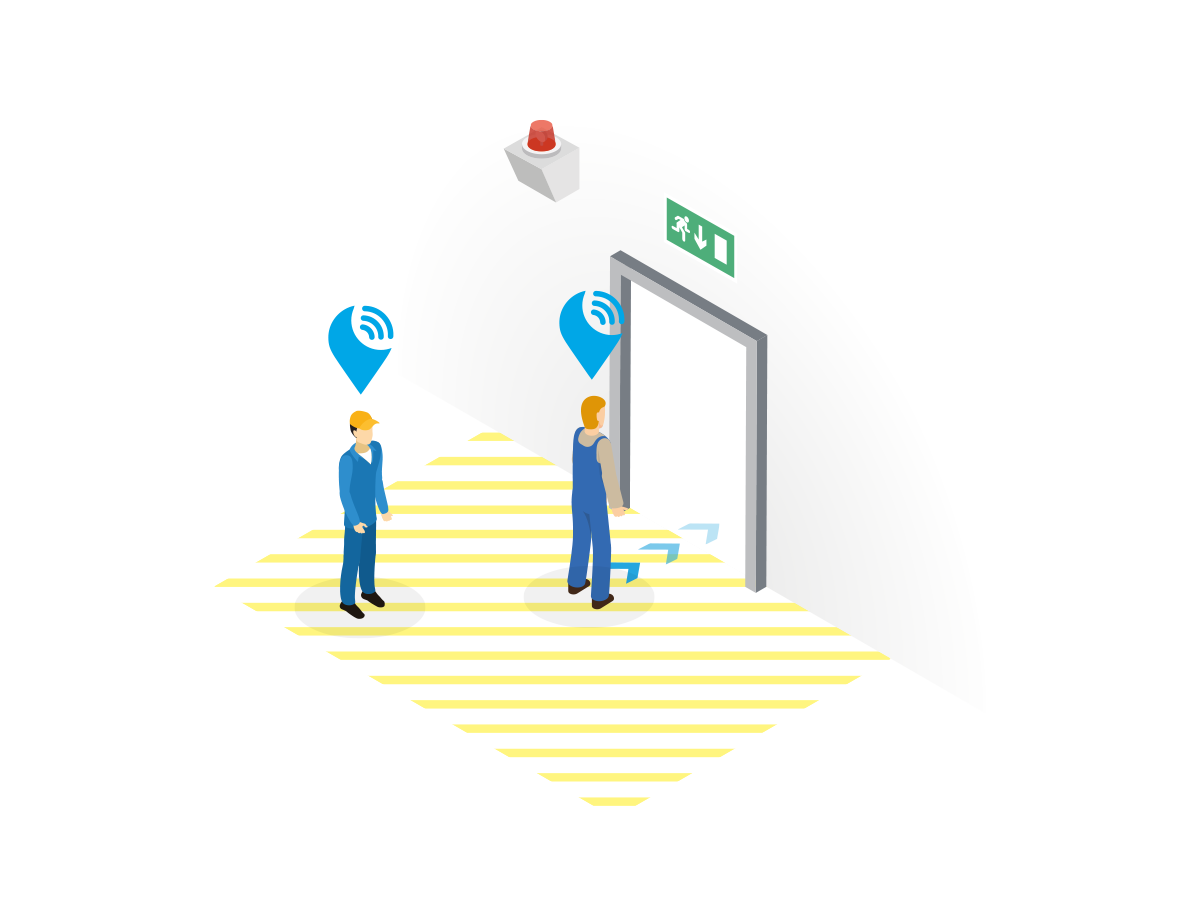

The Be-All and End-All in Companies Is the Employee – Why Not Connect Them as Well?

The focus of an effective digitization strategy is on optimizing existing workflows. By using modern technologies, companies can improve their process efficiency — and at the same time raise work safety to a new level.

Best Practice: Continental

The Fully Automated Material Flow — a Vision Becomes Reality

In just a few years, Continental plans to fully automate its entire supply chain, from planning to product delivery. This requires industry-experienced technology partners to support the global roll-out of several smart applications. KINEXON was selected in the area of geolocation, one of the key technologies of the large-scale project. After only a few months, there has already been initial success.