Order Tracking

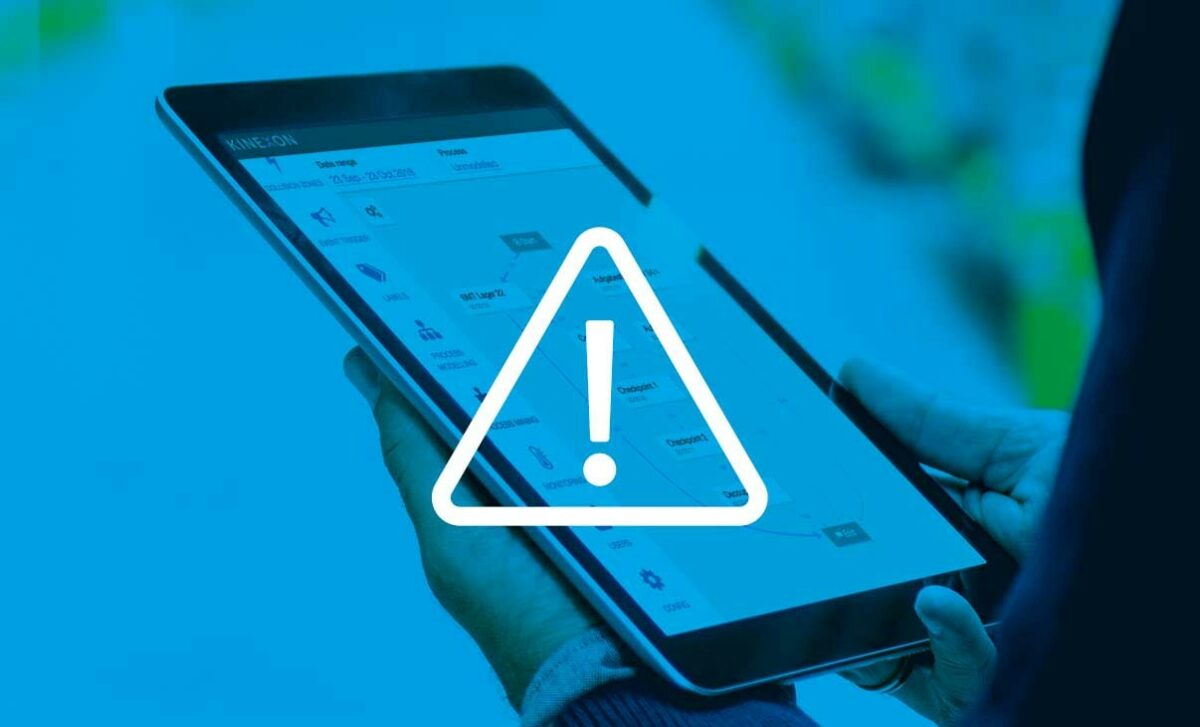

Digitize Your Order Tracking to Optimize KPIs

Capturing real-time location data across all manufacturing operations is essential to systematic order tracking. Based on precise position data, companies can automate manual processes, take immediate action in the event of process violations, and perform analysis to identify bottlenecks. Worker productivity can be increased and process-driven KPIs can be optimized for the long term.

GET IN TOUCH TO LEARN MORE

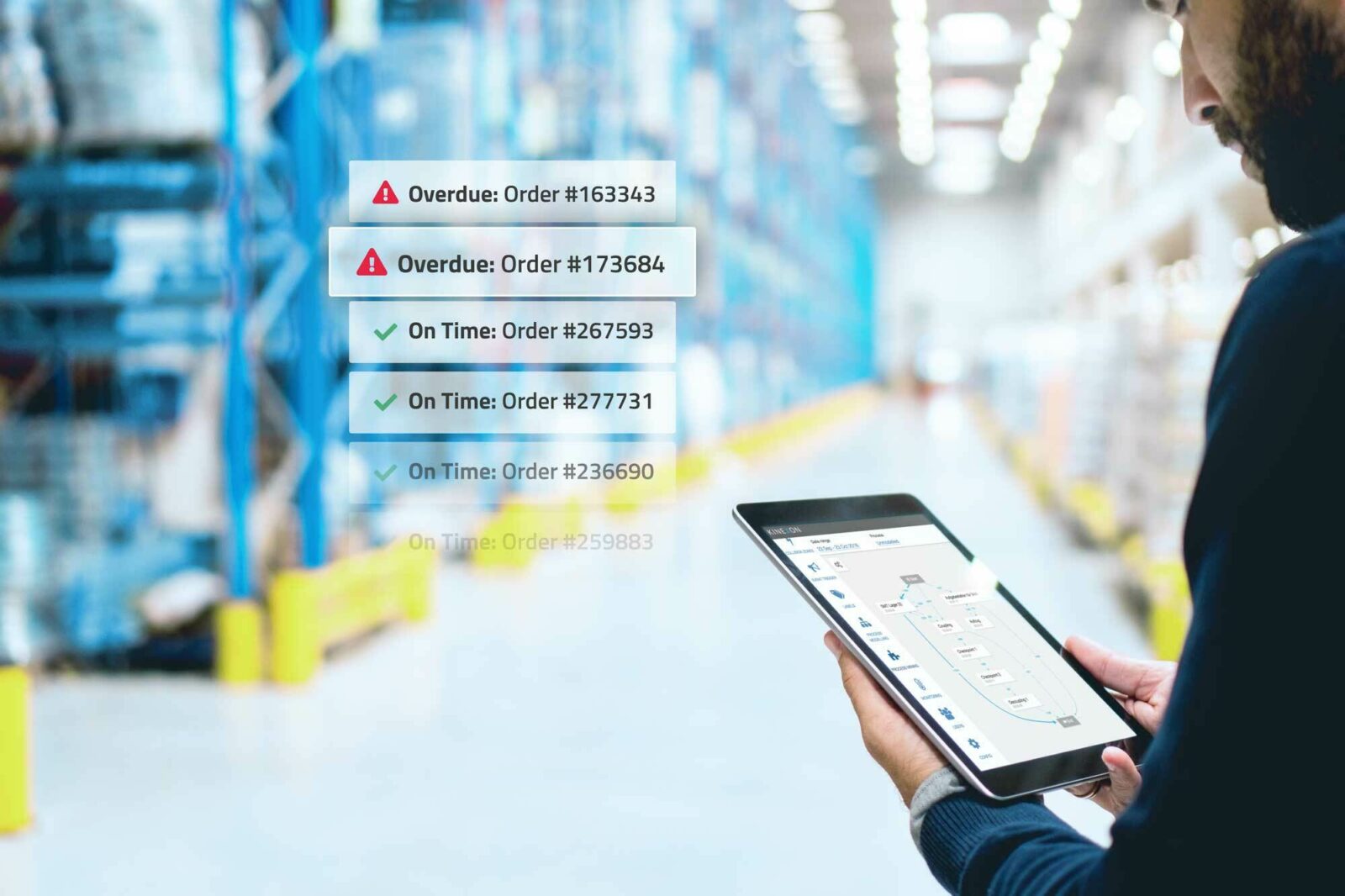

Automated order tracking leverages location technology solutions to apply object-based control dashboards, including effective visualizations of process steps that allow for easy data-driven decision-making.

Today’s main challenges in order tracking

1 | Lack of Transparency:

Unclear batch order status information can result in inefficient order planning. It also hinders traceability when quality problems arise.

2 | Costly Downtimes and Delays:

Delayed detection of process violations, such as a skipped process step, can lead to costly scrap, rework, or repairs.

3 | Complex Production Planning:

Process bottlenecks occur especially at peak times (e.g., overrun of buffer zones, over/under utilization of machines). Changes in production plans further increase the complexity of order handling and process planning.