Continental

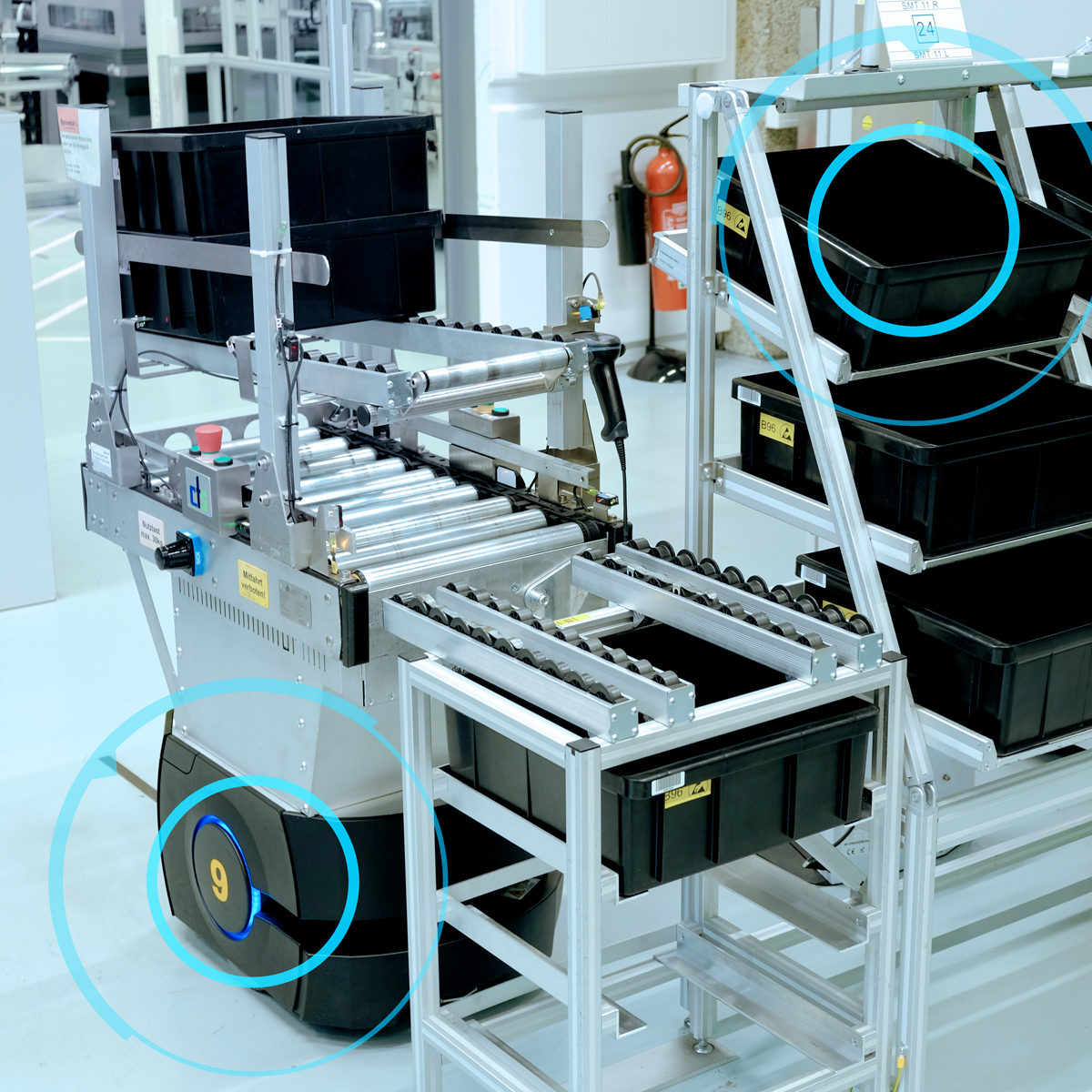

A Vision Becomes Reality: The Fully Automated Material Flow

The entire supply chain, from planning to product delivery, is to be fully automated at Continental. This requires industry-experienced technology partners who support the global roll-out of several smart applications. KINEXON was selected in the geolocation area, one of the key technologies of the major project. The first successes were recorded after just a few months.

Learn more in our case study — or get exclusive insights from the project experts in our webinar!

“We have a clear vision: a fully automated supply chain from planning and production control to physical material flow, that is, from material delivery to production supply to product delivery.”

The material flow at Continental: seamlessly connected, digitalized, and automated.

About the Customer

Continental develops pioneering technologies and services for sustainable and connected mobility for people and their goods. The technology company, founded in 1871, offers safe, efficient, intelligent and affordable solutions for vehicles, machines, traffic and transportation. Continental generated sales of 44.4 billion euros in 2018 and currently employs more than 244,000 people in 60 countries and markets.

The Task

Improving frequently occurring routines and processes in order to subsequently reduce costs, increase efficiency, and increase production speed – these are Continental’s clear goals. Analyses showed: The greatest potential lies in processes involving their material flow. It is therefore important to digitize, connect, and automate them seamlessly.

The Solution

An identified key technology is geolocation. With its RTLS solution, KINEXON not only delivers reliable and precise data, but with KINEXON OS it is also a versatile, compatible and dynamically adaptable real-time IoT solution. In this, all data can be analyzed at the same time and controlled in value-adding applications.

The Result

Guaranteed quality, higher throughput speed, and improved efficiency — Continental achieved this with KINEXON in the first step of the large-scale project in the context of six applications in the model factory in Regensburg. A seventh, to date visionary, application is being developed jointly in a development partnership.

Facts and Figures

KINEXON technology is already in use in a logistics center and three production areas.