STILL's automation solutions integrate with KINEXON to bolster VDA 5050 compliant fleet management.

We drive automated vehicles – under this slogan STILL offers the iGo portfolio: different vehicle-based expansion stages for the automation of intralogistics, which can be individually adapted to individual requirements. iGo systems implement the automated interaction of one or multiple different industrial trucks in order to perform transport tasks in the warehouse without a driver.

Different warehouse situations require individual solutions. iGo systems offers you a perfectly coordinated combination of different automated STILL series-production trucks and corresponding technology, including the installation of all components.

The quality of the iGo systems series devices has been proven in numerous automation projects. Once the tailor-made automation solution has been implemented, a professional service model guarantees that your system is available at all times.

One of these trucks is the EXV iGo systems. Whether in production supply or as an alternative in the pre-storage area – automated EXV high lift pallet trucks deliver the best services wherever they are used.

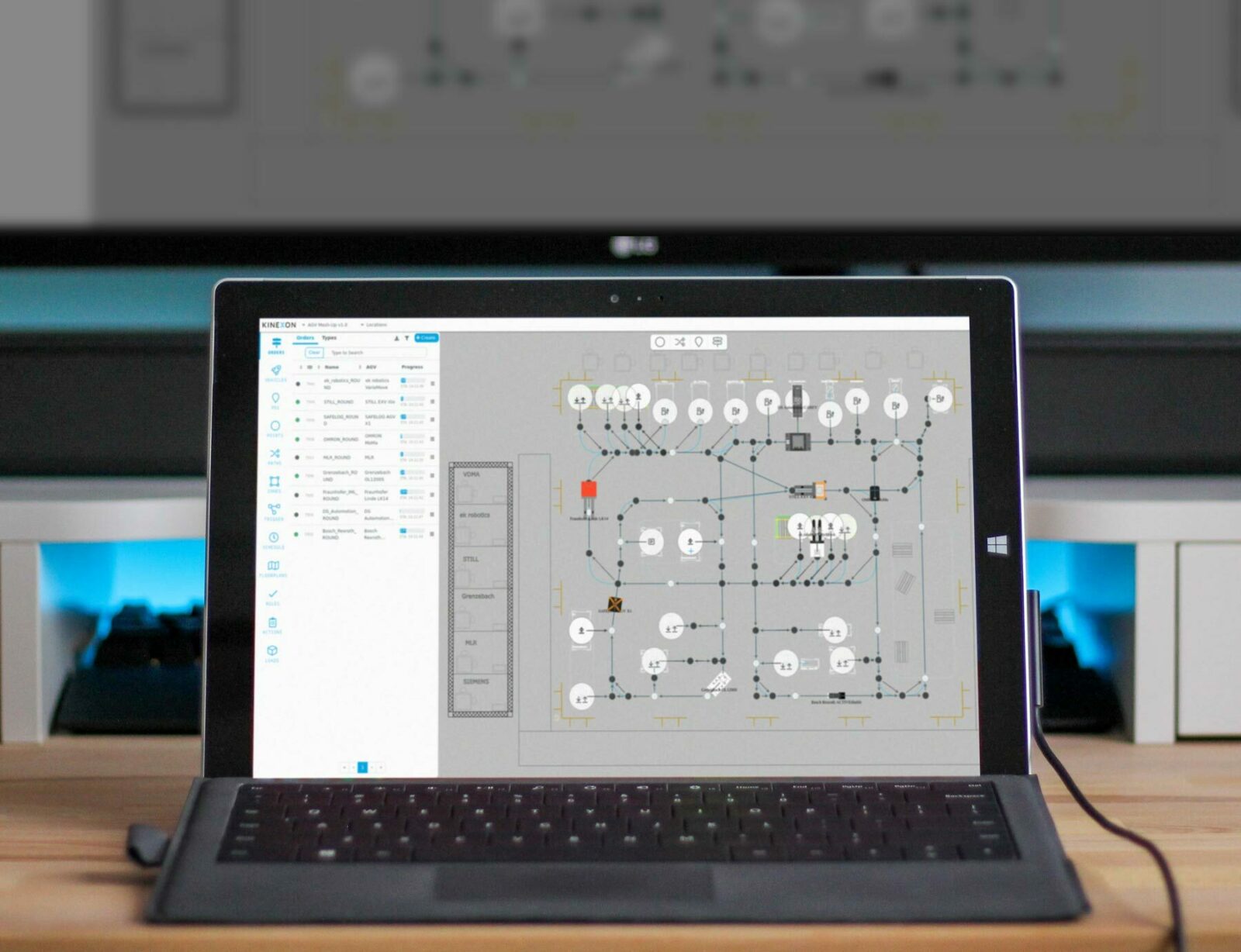

We are happy to announce that the EXV iGo systems automated high lift pallet truck will be one of the vehicles guided by the KINEXON Fleet Manager at the VDMA AGV Mesh-Up Event 2023. In this event, STILL showcases how automated forklifts like the EXV iGo systems from STILL are orchestrated by a VDA 5050 compatible Fleet Manager from KINEXON.

Why is the STILL EXV iGo system so unique?

This is mainly due to the fact that the EXV iGo systems are based on a series-production vehicle that has been enhanced with automation kits with identical components controls and interfaces to turn it into an automated guided vehicle (AGV) in a very short time. From a customer point of view this offers the reliability of series vehicles with series spare parts, which are available more quickly and maintained by the extensive service network of STILL.

Use Cases

Whether in production supply or as an alternative in the pre-storage area – the automated EXV high lift pallet trucks are designed for a wide range of applications: from automatic loading and unloading in wide aisle and use in block warehouses to production supply and disposal up to transport over long distances.

Let’s have a look at possible use cases that can be provided by software like the KINEXON Fleet Manager in combination with AGVs like the EXV iGo systems of STILL:

- Stock transfer: With the automation skill, the EXV iGo systems feeds automated pallet racks from staging areas in front of the truck gates, or from production lines independently. At this point, the KINEXON Fleet Manager connects those third-party systems with the AGV

- Replenishment: STILL EXV iGo systems often comes into play for automated restocking of consumables such as packing materials as well as for replenishment and removal of containers in production processes. By applying IIoT (Industrial Internet of Things) buttons at the consumption point, or more advance by applying an RTLS (Real-Time Locating System), the replenishment orders are triggered through the KINEXON Fleet Manager and appointed to the most suitable EXV iGo systems, considering locations and battery level.

- Intralogistics transport: In this case, the automated high lift pallet truck is guided on virtual paths between Point of Interests by the KINEXON Fleet Manager. For the sake of efficiency, the system considered all vehicles in its overarching traffic management. By this the AGV canalso execute horizontal transport, for example move to and from wrapping machines after palettizing products for storage and shipping.

In the latter case, through its maximum speed of 2.0 m/s, the EXV iGo integrates into existing operation with ease and keeps up the established process speed. Which is made possible through its sophisticated state- of the art build-in safety system: The safety features consist of a 360 Degree pedestrian protection, which uses scanners and sensors to protect people, machines, and loads. Beyond that, the AGV is equipped with optical and acoustic warning devices as well as several standard emergency-stop buttons.

With the ability to underride and lift with its forks, the EXV iGo system is prepared to carry a wide variety of handling units, including EUR Pallets and pallet cages. In addition, customized load carriers deviating from these standards can be tested with regards to the compatibility of the base vehicle (residual load capacity, for length, ….) and the automation system (safety field, load/lift capacity, …).

Due to its VDA 5050 compatibility, the STILL EXV iGo systems can be integrated into the KINEXON Fleet Manager, which enables the interoperability with other AMRs and AGVs of multiple other vendors.

What This Means For You

The STILL EXV iGo systems automated guided vehicle (AGV) offers you reliability with its use of series-production vehicles and identical components. It is designed to improve your operational efficiency and productivity in brownfield production and warehouse logistics, with use cases including stock transfer, replenishment, and intralogistics transport. The AGV is equipped with sophisticated safety systems, including 360-degree safety laser scanners, and emergency stop buttons, to protect your visitors and shopfloor workers. It keeps your shopfloor automation flexible with carrying a wide variety of handling units within market proofed hardware.

In addition, with the integration into the KINEXON Fleet Manager interoperability with other AGVs and AMRs becomes reality. The integration also provides the connecting software layer of KINEXON, which integrates the EXV iGo systems into existing IT structures such as ERP and WMS with ease.

Join Us for the 2023 AGV Mesh-Up!

Don’t miss out the next step towards your future ready and resilient shopfloor operation with flexible automation by STILL and KINEXON that improves your business’s efficiency and productivity. Join us at the VDMA AGV Mesh-Up Event 2023 and experience how automated forklifts are orchestrated in a mixed fleet with other AMRs and AGVs by a VDA 5050 compatible Fleet Manager.

Get in touch with us today to learn more about the revolutionary EXV iGo system and how it can benefit your organization.