OMRONs automation solutions as part of the VDA 5050 fleet management

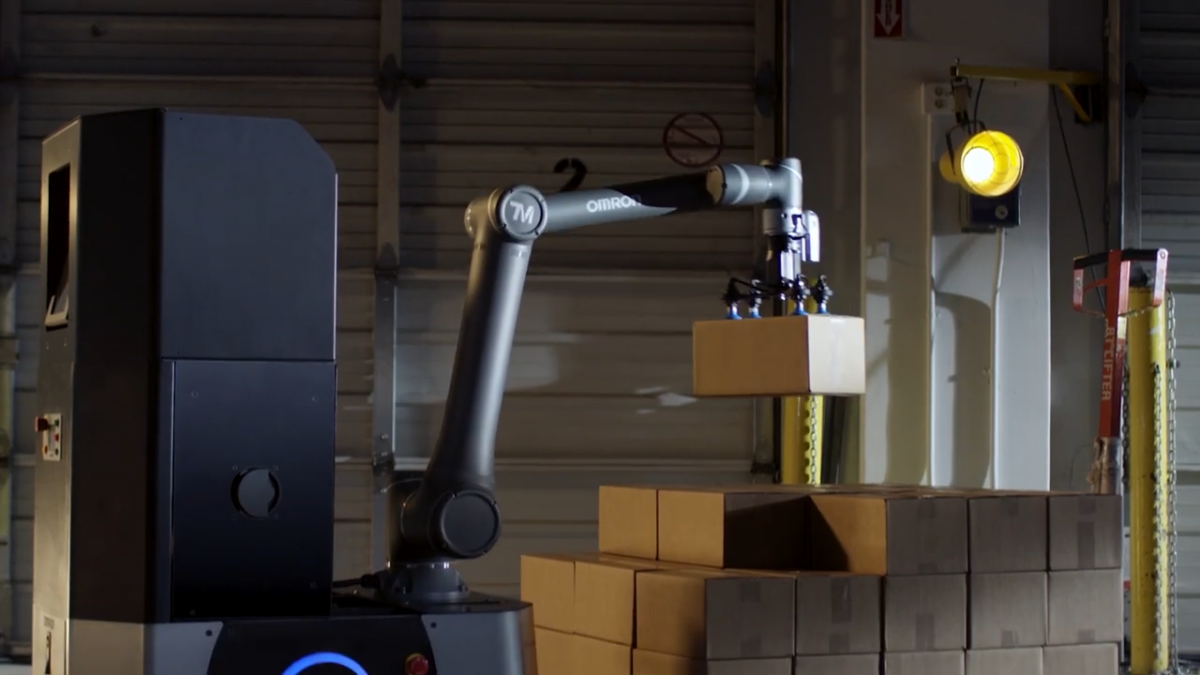

The world of automation and robotics is rapidly evolving, and the latest innovation from OMRON is making waves in the industry. The Mobile Manipulator, a combination of Cobot and the Autonomous Mobile Robots (AMR), is set to revolutionize the manufacturing and intralogistics processes. Seamlessly integrated into the KINEXON AMR & AGV Fleet Manager, this technology boasts a standard interface of VDA 5050, promising to boost productivity and efficiency for businesses across industries.

The next era of intralogistics

With the Mobile Manipulator taking over manual and hazardous tasks from shop floor workers, this development is a game-changer for the manufacturing and logistics industries. Are you ready to take your business to the next level? Learn more about this integration’s quick facts, why it’s critical, which industries will benefit the most, and valuable tips for companies investing in shop floor automation.

What This Means For You

The hybrid combination of Cobot (collaborative robot) and AMR (Autonomous Mobile Robots) creates new standards for customer value and flexibility in the manufacturing and intralogistics operations. Guided by the KINEXON AMR & AGV Fleet Manager, Omron’s Mobile Manipulator supports the shopfloor team. With the VDA 5050-compliant interface, our Fleet Manager provides the Mobile Manipulator with configured orders from the ERP, WMS or for example WCS.

Through this powerful partnership, manufacturing and intralogistics processes like the following can be automated to withstand the labor shortage and market volatilities:

- Material handling and transportation: The Mobile Manipulator can move materials and products between different locations within a facility. With the traffic management in the KINEXON Fleet Management, the Mobile Manipulator is navigated on the optimal route and without interference of other AMRs and AGVs, or locked gates.

- Order fulfillment (picking and packing): With its collaborative robotic arm, the Mobile Manipulator can pick and pack items or even boxes. This can apply for example, through triggering a Kanban restocking order via an IIoT-Button in our Fleet Manager. Therefore, the need for manual order placing, assigning, and transferring gets reduced significantly and efficiency increases.

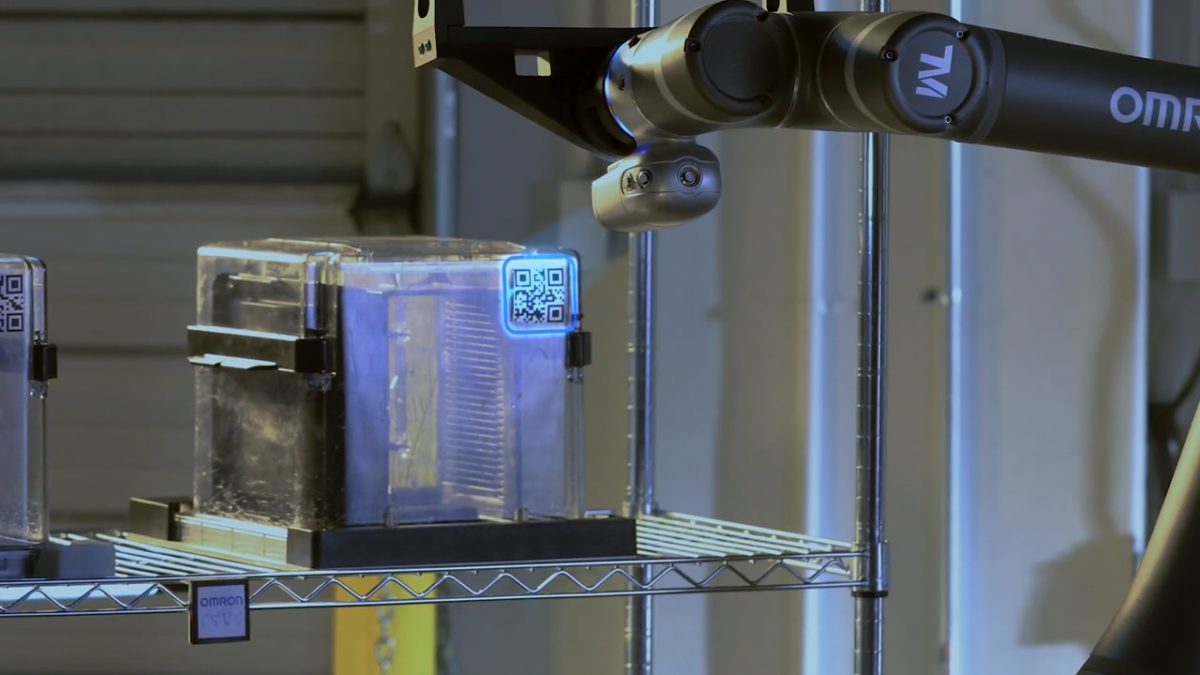

- Inventory management: By applying an onboard camera, inventory checks can be executed. By scanning barcodes on the storage location and the goods, inventory counts are automated, improving accuracy and speed.

- Quality inspection: The onboard camera of the Mobile Manipulator is also able to inspect products and materials for defects, reducing the risk of defective products reaching customers.

- Machine tending: With its flexibility, the Mobile Manipulator can assist the assembly and manufacturing processes at various workstations throughout the day. The vehicle safety features allow the continued performance of repetitive or physically demanding tasks alongside human workers.

- Disposal: One key benefit of the KINEXON integration is the shared filling level of machine waste bins, coupled with capacity rules that trigger a disposal order. Additionally, the suitably equipped Mobile Manipulator is provided with the paths to the pick-up and drop-off locations for its execution. The KINEXON Fleet Manager also includes restriction zones around the machine, ensuring that the AMR isn’t affected by other passing AGVs or AMRs during the granular picking process.

Omron’s Mobile Manipulator is the shopfloor workers friend, automating these time-consuming and manual tasks, allowing workers to concentrate on more complex assignments, and therefore more value creating jobs. Beyond that, with taking over the work in hazardous environments, the Mobile Manipulator can reduce the risk of workplace accidents and injuries, leading to a safer and healthier work environment. The Mobile Manipulator can also work during nightshifts and through legal holidays, which assists in directly lowering labor costs.

Enhance Your intralogistics with OMRON's Mobile Manipulator and KINEXON Fleet Manager

In conclusion, OMRON’s Mobile Manipulator, with its combination of Cobot and AMR technology, is revolutionizing the factory and intralogistics environment. And with the KINEXON Fleet Manager, businesses can take full advantage of this innovative solution, making their manufacturing processes more efficient, agile, and adaptable to market volatilities and general uncertainty.

With the Mobile Manipulator’s game-changing flexibility and the KINEXON Fleet Manager’s real-time tracking and positioning capabilities, companies can optimize their operations, improve safety and security, and enhance productivity. This cutting-edge technology is designed to take your business to the next level, helping you stay ahead of the competition and achieve your goals. Don’t get left behind in the rapidly evolving world of automation and robotics – embrace the power of OMRON’s Mobile Manipulator and KINEXON Fleet Manager today.

How OMRON and KINEXON Will Help You With the AMR Fleet Manager Solution

Companies looking to improve their manufacturing and intralogistics should consider investing in this technology to take their operations to the next level. For a personal impression you can visit Omron in their new Robotics Center in Dortmund, Germany.

We’re in the starting blocks and will be happy to consult you on the topic of modern fleet management.

Contact us