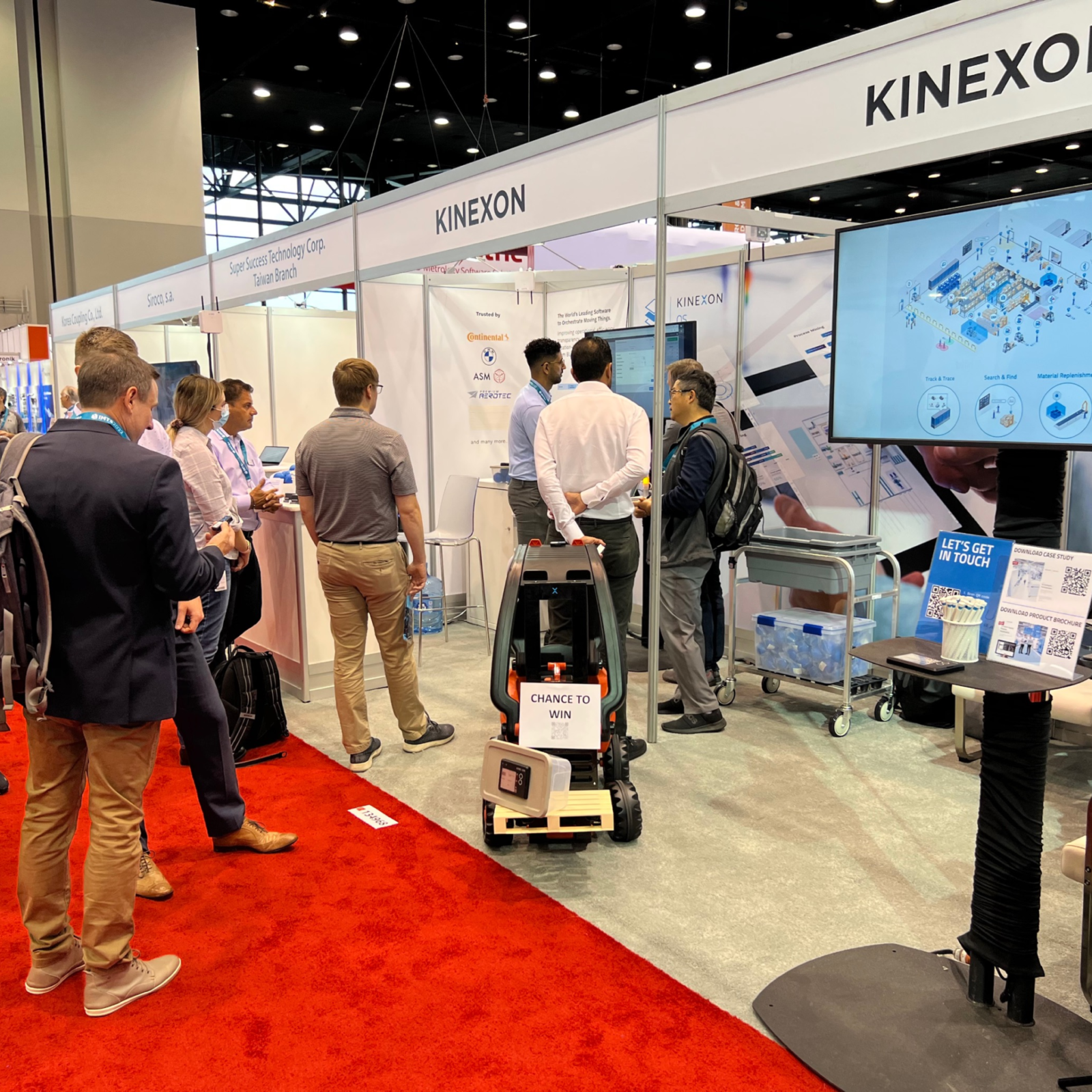

Assembly Show Wrap Up

What a week it was at the 2022 Assembly Show! Our team spent the three-day event conversing with potential clients, as well as enjoying some amazing local food and drinks with the manufacturing community at the KINEXON Breakfast Morning Mingle. Read on to learn more from our VP of Sales IoT, Tinos Kountroubis, about his experience at the show.