KINEXON Mesh: The Reasons Why Industrial Asset Tracking and Optimization Just Got Better

At KINEXON, we strive to provide our customers with the best solutions tailored to their needs and goals. Our latest innovation, KINEXON Mesh, is a game-changing technology in the world of IIoT. With Mesh, companies of any size can now more effectively track the location and connect industrial assets, optimizing shopfloor and warehouse operations like never before.

KINEXON Mesh is a UWB-based locating system that offers the ideal blend of accuracy, reliability, and user-friendly scalability which is also cost effective: businesses can expect a swift payback period, typically within two years — and sometimes even within one year.

Considering the vast number of industrial assets involved in global operations and manufacturing logistics, it is surprising that only a fraction of them are currently connected and managed. KINEXON aims to revolutionize this landscape with our automated solutions for the automotive, aerospace & defense, intralogistics, and machinery & equipment industries.

With the combination of Mesh technology and the KINEXON Operating System, companies get the best combination of connectivity, IIoT sensors and automation software. The KINEXON Operating System manages the location data and supports customer use cases such as inventory management, where the positioning is provided via a customer-centric user interface.

On top of providing the right data to the right user on the shopfloor, the integration of data in topfloor systems like ERP, MES, and warehouse management systems can also be implemented to optimize and automate operations.

The Business Value of KINEXON Mesh

KINEXON Mesh is our latest RTLS (Realtime Locating System) for our asset tracking solution, requiring minimal IT integration when compared to other RTLS systems. As it’s cloud-based, any company of any size can implement it and see real-time data for their assets.

1. Maximum cost efficiency

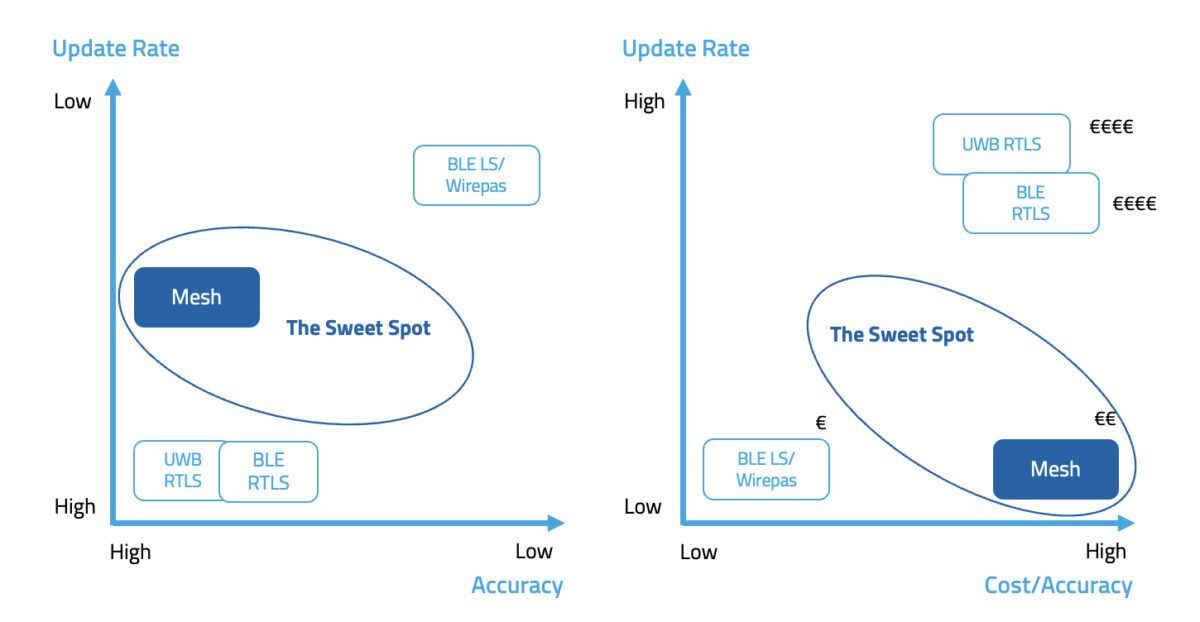

We’ve made sure that Mesh is flexible and easy to install – it’s truly a plug-and-play RTLS. It literally requires just one wire to set up the whole system in any warehouse of any size. We also ensure that in terms asset location accuracy, it offers unparalleled centimeter-accuracy and the flexibility of a BLE (Bluetooth-enabled low energy) system – all at a fraction of the cost of other RTLS’.

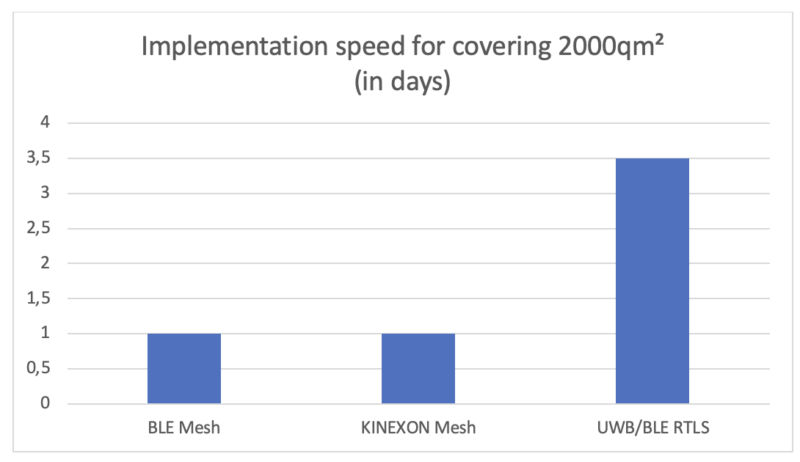

2. Fastest deployment for UWB-based asset tracking solutions

On top of that, when it comes to deployment of the UWB-based system, KINEXON Mesh is cloud based, which means that there is no dependency on local IT for deployment, and world-class security features come with it, based on how we deploy it on the cloud.

With the Mesh locating system, we can literally cover the area of three soccer fields in just day, which is roughly 21,000 square meters or 230,000 square feet. What this means is that we offer a 90% reduction in implementation time compared to other tracking systems.

3. Full integration and scalability

With the cloud-based integration of KINEXON Mesh into our software stack, we provide:

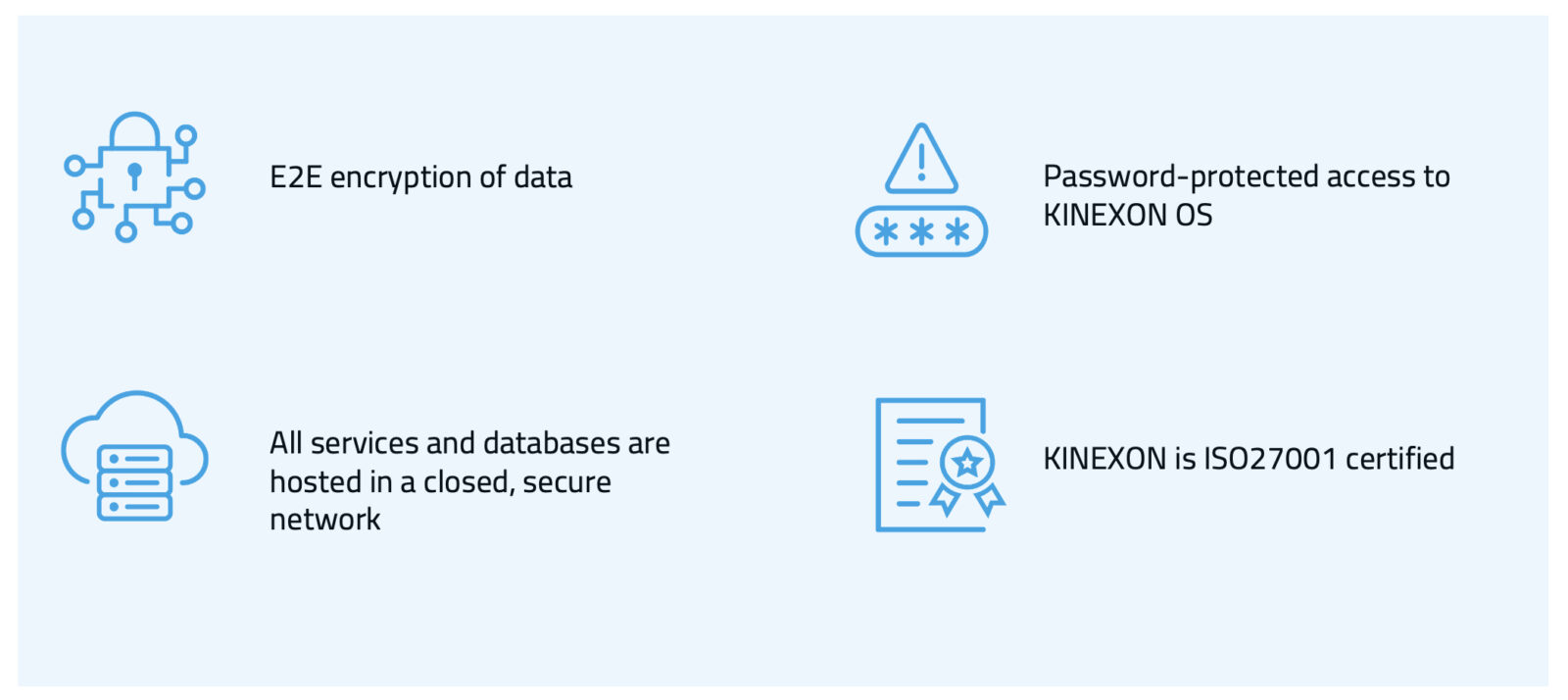

- E2E encryption of data via VPN, TLS, network communication encryption and MQTTS user authentication

- All services and databases are hosted in a closed, secure network, in separate regions in Europe or the United States

- Password-protected access to KINEXON OS, including role and rights management for user-specific data access. Authentication via LDAP is possible.

- KINEXON is ISO 27001 certified: ISO 27001 is the international standard for information security.

Our offer enables customers to start with the KINEXON Operating System and seamlessly integrate the KINEXON stack in a new or existing software environment, scaling up the solution with more use cases and applications as business needs grow.

4. New fields of application

With the asset tracking solution from KINEXON, companies can improve the overall visibility of all assets, reduce inventory management costs, and reduce process violations and manual coordination efforts with increased workflow management / process flow management.

Using the Mesh locating system, companies can track assets indoors, outdoors (from 2024), and throughout yards and factories. This means businesses will benefit from the most updated asset locations as well as the best possible analytics and data behind how the assets are moving.

Mesh is suitable for larger industries and bigger warehouses and moreover, even smaller SMEs can use the technology and realize the benefits that come with it.

How Mesh Meets Global Challenges

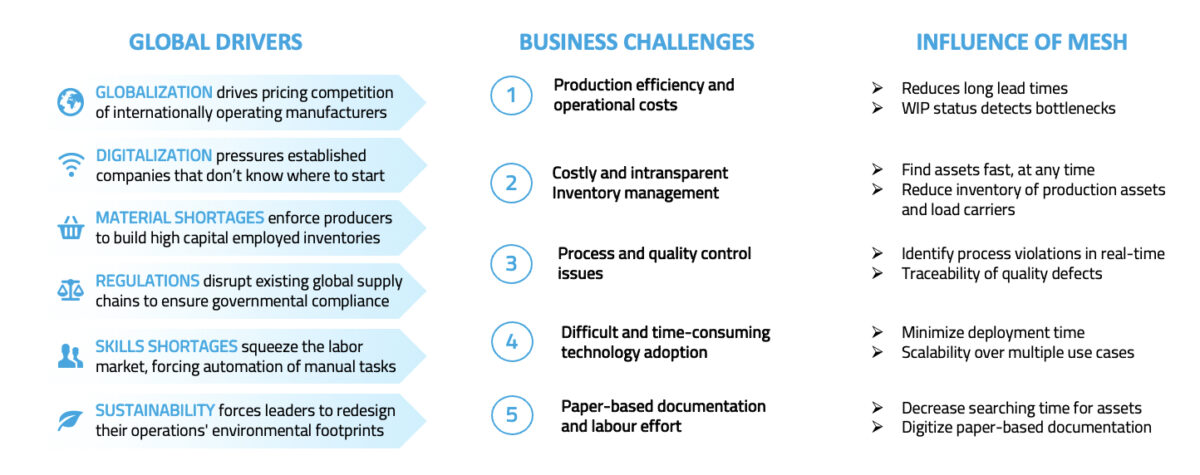

One of the key drivers in the business world is globalization, which intensifies pricing competition among internationally operating manufacturers. For example, one of the major challenges for businesses is maintaining production efficiency and managing operational costs. This is where the influence of KINEXON Mesh comes into play.

By implementing the asset tracking solution from KINEXON with the Mesh locating system, companies can reduce employee workload and significantly increase efficiency through a decrease in long lead times and real-time visibility gains into work-in-progress (WIP) status. This enables employees to proactively identify and address operational bottlenecks, ensuring smoother workflows and improved productivity.

The technology of KINEXON Mesh introduces an innovative, scalable, and accurate approach that facilitates the efficient management of assets for shopfloors and warehouses to meet the global challenges that manufacturers face. With fast integration times, high scalability and reliability, UWB-based locating systems like Mesh will drive the new standard in manufacturing and logistics.

Industries are continuously evolving, and UWB technology can play a vital role in shaping the future of asset tracking and inventory management. By adopting KINEXON Mesh and automated asset tracking and management, businesses can truly optimize their operations – now and in the future.