How Mesh Locating Technology Boosts Asset Tracking and Management, Saving Production Time and Costs

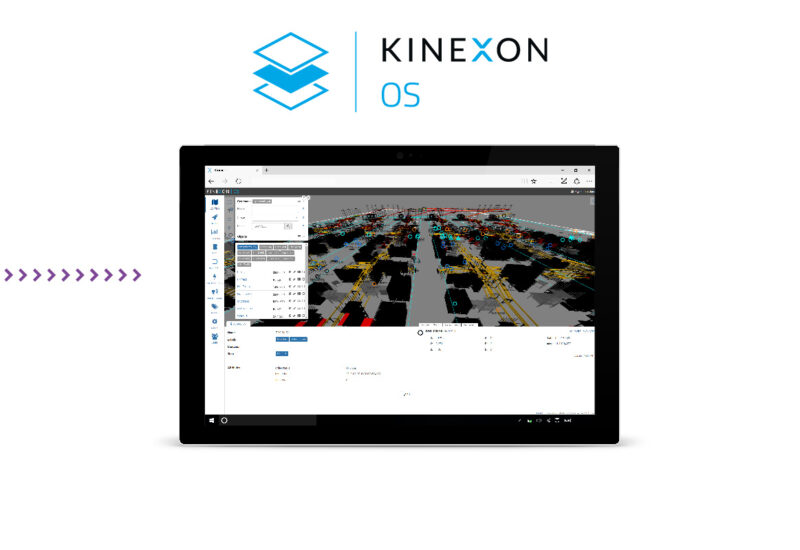

With the innovative KINEXON Mesh locating system, we empower our customers to streamline their search efforts and effortlessly track and manage all assets. This comprehensive system offers a near real-time overview of assets, resulting in reduced costs caused by over and underutilization. By optimizing resource allocation, businesses can enhance production efficiency, making operations more cost-effective and resource efficient.

Optimize Inventory Management and Process Flow with Asset Tracking

Businesses of all sizes can Improve inventory and process flow management with our asset tracking solution, powered by the KINEXON Operating System and KINEXON Mesh locating system. Our asset tracking solution enables a new way of automating inventory management and optimizing process flow management for shopfloor and warehouse assets, significantly reducing search efforts and saving costs. Companies can enhance process flow management with transparency and immediate identification of assets, delays, and lead times.

Inventory management

When it comes to finding production assets, shopfloor employees experience high search times and often count stocks manually: these manual efforts often lead to delays in follow-up processes. Powered by the KINEXON Operating System, with our asset tracking solution using KINEXON Mesh, customers have full transparency on the location and status of their assets and can visualize them for factory and warehouse employees in almost real-time, which leads to:

- Reducing search efforts by approximately 4 hours per shift, resulting in cost savings of more than USD $100,000 per year.

- Decreasing manual efforts in warehouses, resulting in time savings of approximately 10 minutes per search.

Process flow management

Lack of transparency of WIP (Work-in-Progress) status inside processes and rule-based controlling orders leads to the slowing or stopping of production. However, workflow bottlenecks can be visualized and eliminated. With the KINEXON Operating System, customers have full transparency over the workflow and the immediate identification of lost assets, process delays, and process lead times. Customers benefits include:

- Saving personnel costs of EUR €50,000 per year by decreasing time spent searching for lost assets.

- Reducing process delays by 15% over time.

- Saving more than EUR €20,000 per year on new equipment and double production due to losses of production orders and knowledge of usage rates for existing working materials.

- Decreasing cycle times by 10% by removing all process delays and receiving instant alerts on any violations

Enhancing Efficiency for Production and Logistic Planners, Supervisors, and Shopfloor Workers

Experience the benefits of our asset tracking solution for planners, supervisors, and shopfloor workers.

Production and logistic planners

With a payback period of just 1 – 2 years, the initial implementation of KINEXON Mesh technology will yield quick success for production and logistics planners. With its beneficial cost/benefit ratio, minimal infrastructure, and straightforward implementation, planners will experience significant savings right away.

Implementing Mesh is a pivotal step towards achieving long-term success for any company’s digitization strategy. Additionally, the integration of a wide range of use cases, technologies, and third-party systems enhances scalability and averts isolated solutions to solve these challenges.

Supervisors

Supervisors will greatly benefit from the 100% transparency provided by our asset tracking solution. They will no longer have to deal with the extra effort of coordinating tasks due to asset losses or rescheduling. With our overview board on asset status and location areas, supervisors can easily track and manage assets in real-time.

Furthermore, the solution automatically captures and updates the status and dwell times of all assets — including their WIP status — within process geofences.

Shopfloor Workers

Our current customers are cost-sensitive for primarily two reasons. First, there are high costs associated with manual labor. Now, either you have labor, which is expensive, or in some cases you don’t even have enough labor to address your main concerns. Now, let’s assume you get that labor, and that labor is working on the shopfloor – unfortunately, it is likely still not digitized.With our asset tracking solution, employees will increase productivity through interactive and easy to use tools. For example, tools for shopworkers provide an easy way to find assets — along with a helping overview — and to visualize dwelling times of assets, sending alerts in cases of process / rule violations for immediate interaction and problem solving..

The Benefits of Asset Tracking for Efficient Asset Management and Insights

Asset tracking provides a valuable automated solution for businesses looking to locate and manage their assets effectively. It is widely used across various industries by small and medium-sized customers.

The primary business requirements for implementing asset tracking and the Mesh locating system are cost-effectiveness, the ability to search and find assets quickly, and a quick and easy installation process. By integrating our asset tracking solution, businesses gain valuable insights into their production and logistics environments, ultimately maximizing cost efficiency in factories and warehouses.