Employee Protection & Work Safety

Employee Protection - the Essential in Times of Corona

The world stands still — around the globe, companies are fighting the spread of COVID-19 and while many productions are pressing the pause button, other companies are trying to keep their plants running. One highlight topic in these times: the protection of employees and in this context also “social distancing”. Real-time localization can make a significant contribution and ensure operation in times of corona. Our client ASM proves that this works!

"In KINEXON OS, we can verify if our measures work."

“We must ensure social distancing in order to protect our employees. But we also have to keep production running at the best possible rate to get through this crisis economically. So, on the one hand, we have asked our employees to always keep several meters distance on the shop floor. On the other hand, they should also avoid meeting at shift changes. In KINEXON OS, we can verify if these specifications work on the shop floor.”

Social Distancing: The Technical Solution

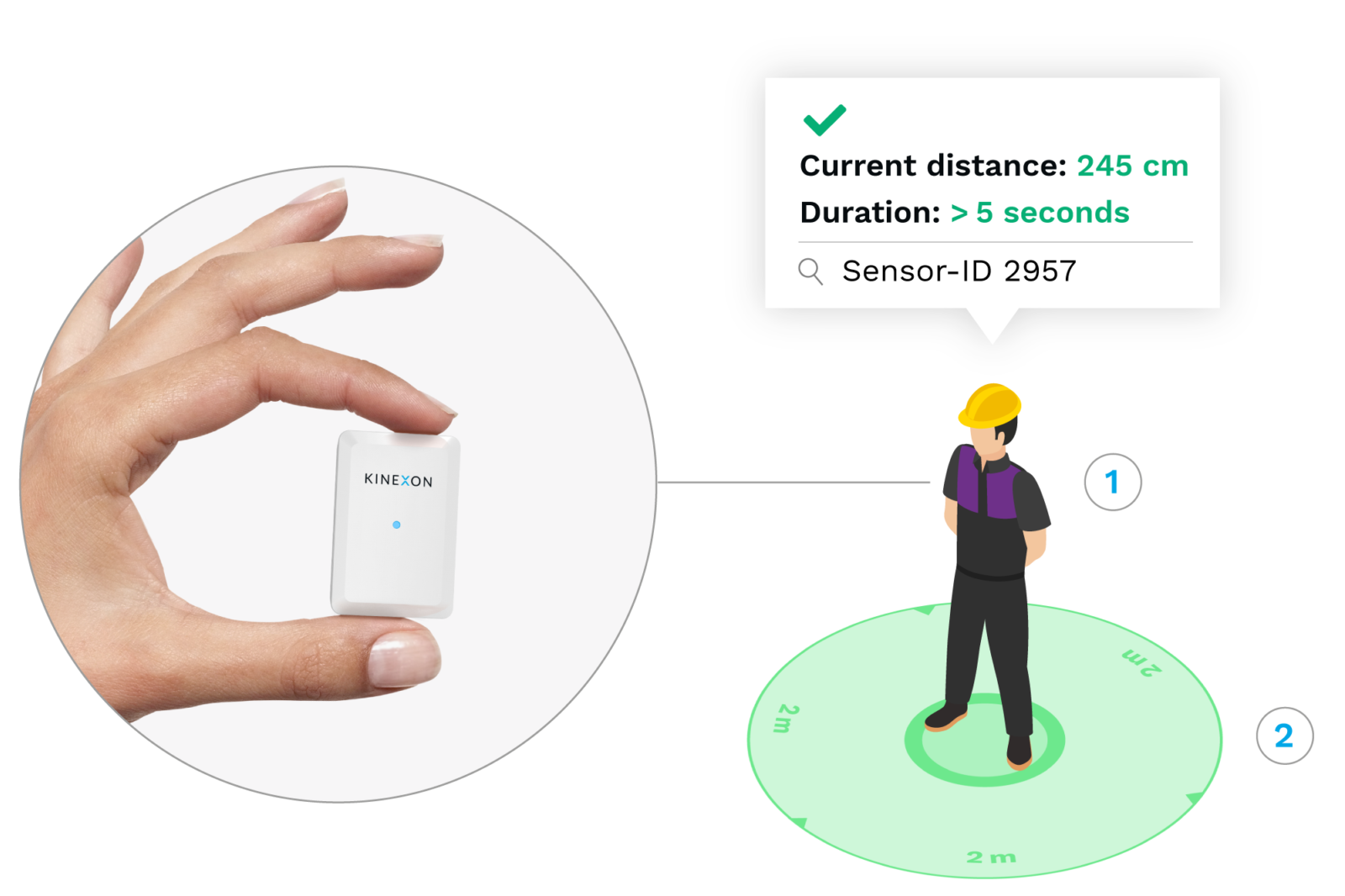

- Distances and contact times are recorded with centimetre accuracy and in real time.

- Besides distances, contact intensities can also be determined.

Get to Know Our Solution: KINEXON SafeZone

Data protection compliant, highly scalable and ready for industrial use: With our latest solution, companies ensure efficient and reliable social distancing while simultaneously securing operations in the event of a COVID-19 infection.

In the Beginning It Was Only About Optimizing the Shop Floor Usage...

In 2019, KINEXON provided an ASM production facility with its own real-time localization system. The initial goal was to optimize the shop floor utilization. However, the rapid spread of COVID-19 required fast and agile action — the application was quickly expanded. Through the anonymous live tracking of the employees, it can now be tracked whether social distancing has been adhered to, e.g. during a shift change.

“We are in a time where solidarity is essential. Because it is more important than ever to show mutual care and to keep a minimum distance of 1.5 metres to fellow human beings. Social Distancing is one of the most important actions against Corona. By getting everyone involved and sticking to the rules, we prevent the further spread of the virus. Even in China or South Korea, social distancing seems to have made a decisive contribution to containing the outbreaks.”

At a Glance: Use Cases in Times of Corona

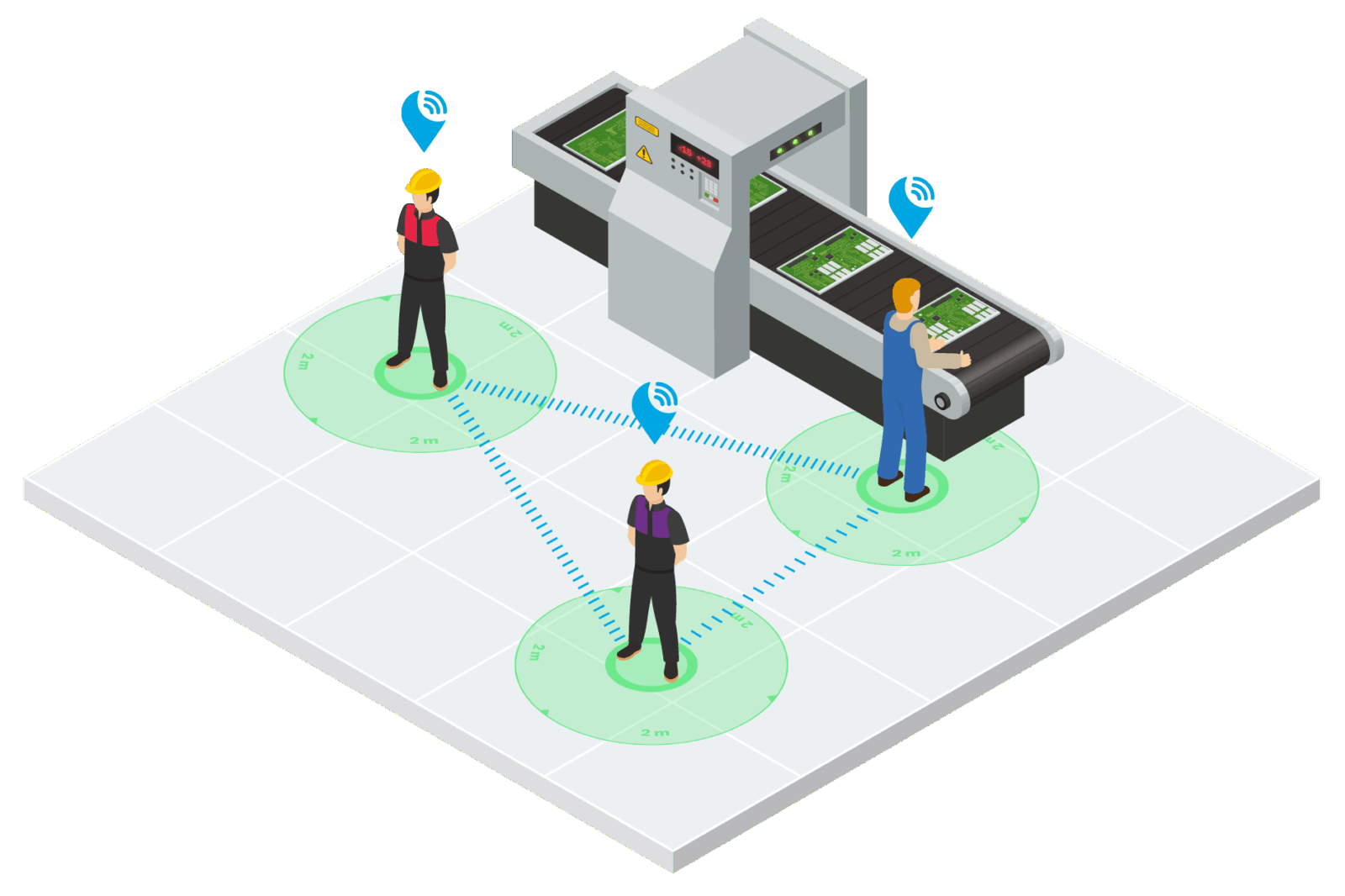

With Real-Time Locating Systems, RTLS for short, people and objects can be located and analyzed in real time. The KINEXON RTLS is one of the most performant systems on the market in the industrial sector and offers unlimited possibilities for new use cases thanks to the flexible location-based process automation software KINEXON OS.

While the UWB-based RTLS was originally used for smart data-based efficiency increase of production processes, KINEXON developed it further to a powerful tool in the fight against corona: KINEXON SafeZone.

Social Distancing

Real-time localization and social distancing — the ideal match: With KINEXON SafeZone, employees are warned with centimetre precision and immediately if they do not keep the minimum distance. This protects employees and ensures production.

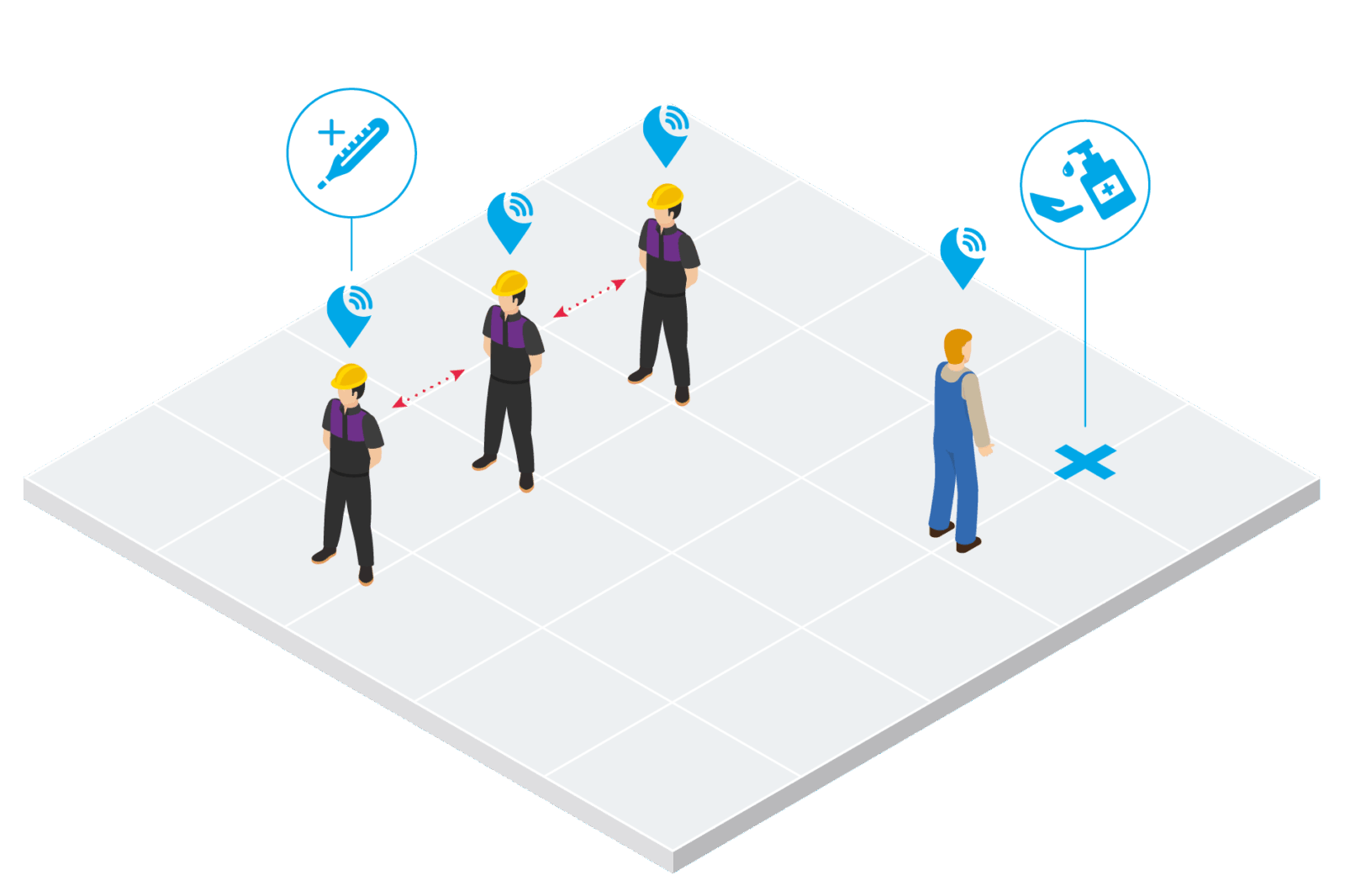

Analysis

Prevention as the highest priority: With KINEXON SafeZone, companies trace infection chains seamlessly and compliant with data protection. In addition, perfect spots for disinfection stations can be identified and measures taken can be checked.

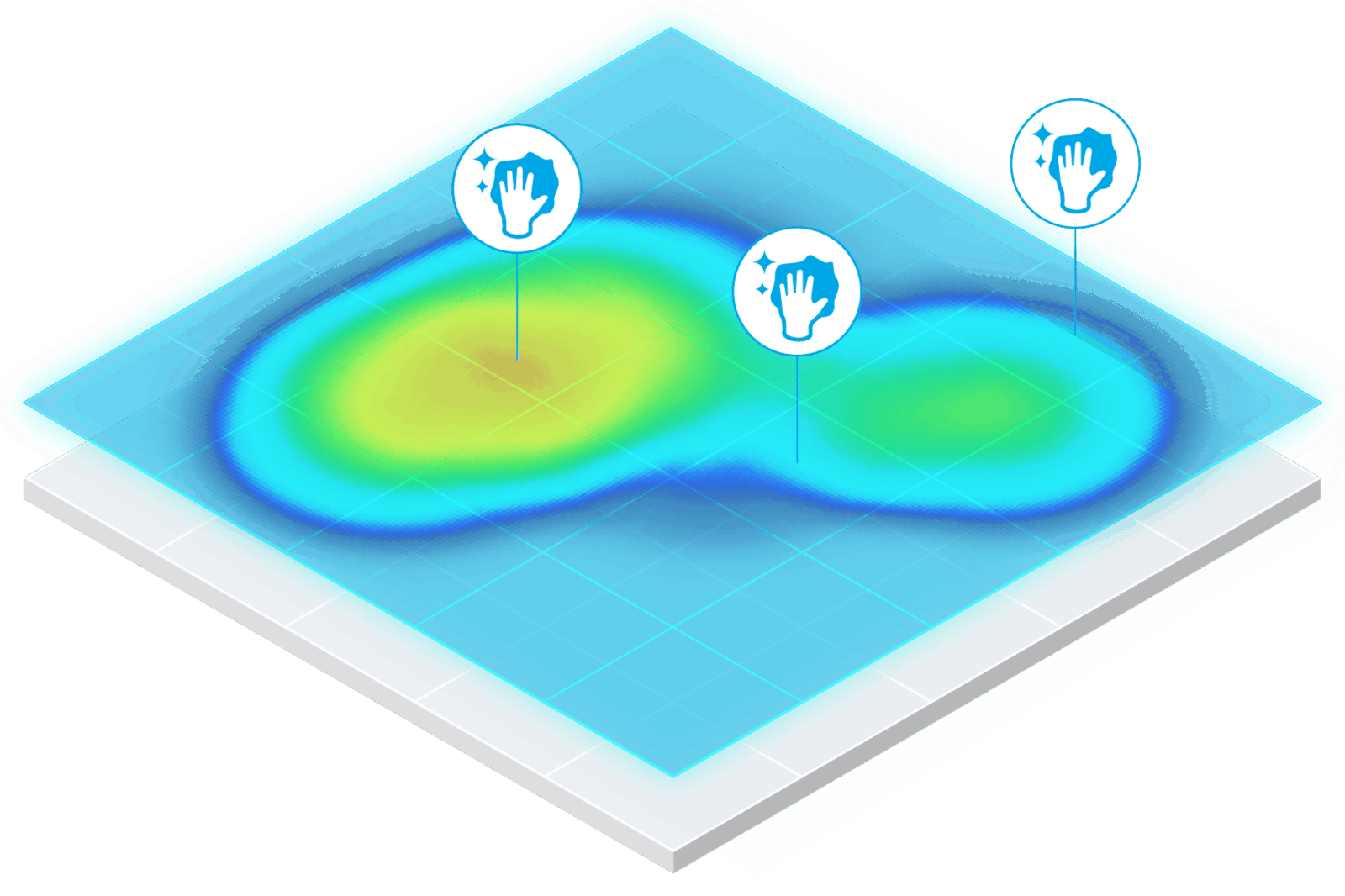

Digital Hygiene Twin

Cleaned up: With the upgrade of KINEXON SafeZone with KINEXON RTLS, cleaning staff can be tracked anonymously. In this way, it is possible to track which areas have been cleaned for how long. In times when thorough disinfection is essential, a helpful feature.

Employee Protection 4.0 - Beyond COVID-19

Even beyond extraordinary situations, such as the worldwide spread of Corona, efficient employee protection and work safety is fundamental for every company. Employers are responsible for creating a safe working environment for their employees.

This is particularly essential in view of the challenges of an increasingly fast and demanding working world due to digital change. Real-time localization offers numerous sustainable and easily scalable use cases.