KINEXON Fleet Manager

It's Time to Set up Your Modern Fleet Management Now

Autonomous mobile robots (AMRs) and Automated Guided Vehicles (AGVs) are conquering the market. Needless to say, efficient and cost-effective management is vital!

The VDA5050 compliant, KINEXON AMR and AGV Fleet Manager provides a flexible, customizable, and scalable, real-time operating system for fleets in production and logistics. Due to its manufacturer, and hardware-independence, it’s possible to manage different kinds of vehicles with ease.

The Challenges You Face and How We Make Life Easier for You

Are you a shop floor manager or a central process expert? Are you looking for a way to simplify managing multiple robots, such as AMRs or AGVs, for your production and logistic processes? We have a full stack solution that:

- Operates on various vehicles and vehicle types, regardless of the communication protocol used

- Deploys on all VDA5050 iterations simultaneously

- Does not require a customized interface to ERP or WMS systems

Your Challenge, Our Solution

Companies are facing an unprecedented labor shortage, but have personnel intensive processes on their shop floor, which requires automation.

As a full-stack, IIot provider, we add our AMR and AGV Fleet Manager into our location intelligence platform. As a result, we provide companies with end-to-end services, and assist them along their automation journey.

Transporting goods of various size and weight requires the use of different robots for a fleet. This leads to too many different shop floor vehicles with their own, individual software and interfaces.

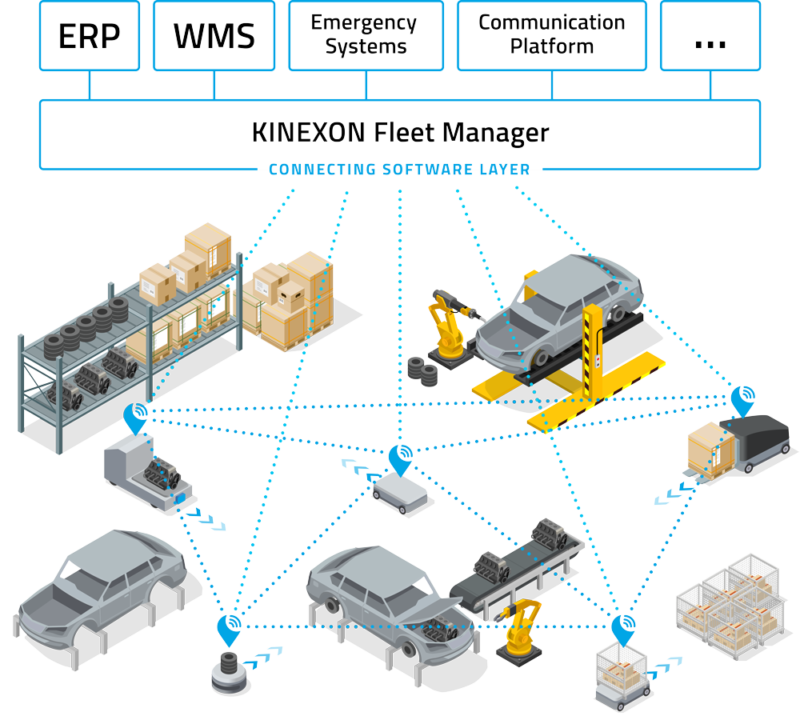

Our Fleet Manager provides a tailored, singular system for each user. Going further, we build layers between customers’ systems and their AMRs and AGVs, to other systems. These systems include ERPs, WMS, fire protection or communication systems, and many more.

Companies want to extend their initial automation solutions, but problems with robot diversity include not being able to coordinate with each other, and software is often confusing.

Through our software layer, customers’ diverse IT-landscapes connect to their heterogeneous group of AMRs and AGVs, on the shop floor with ease.

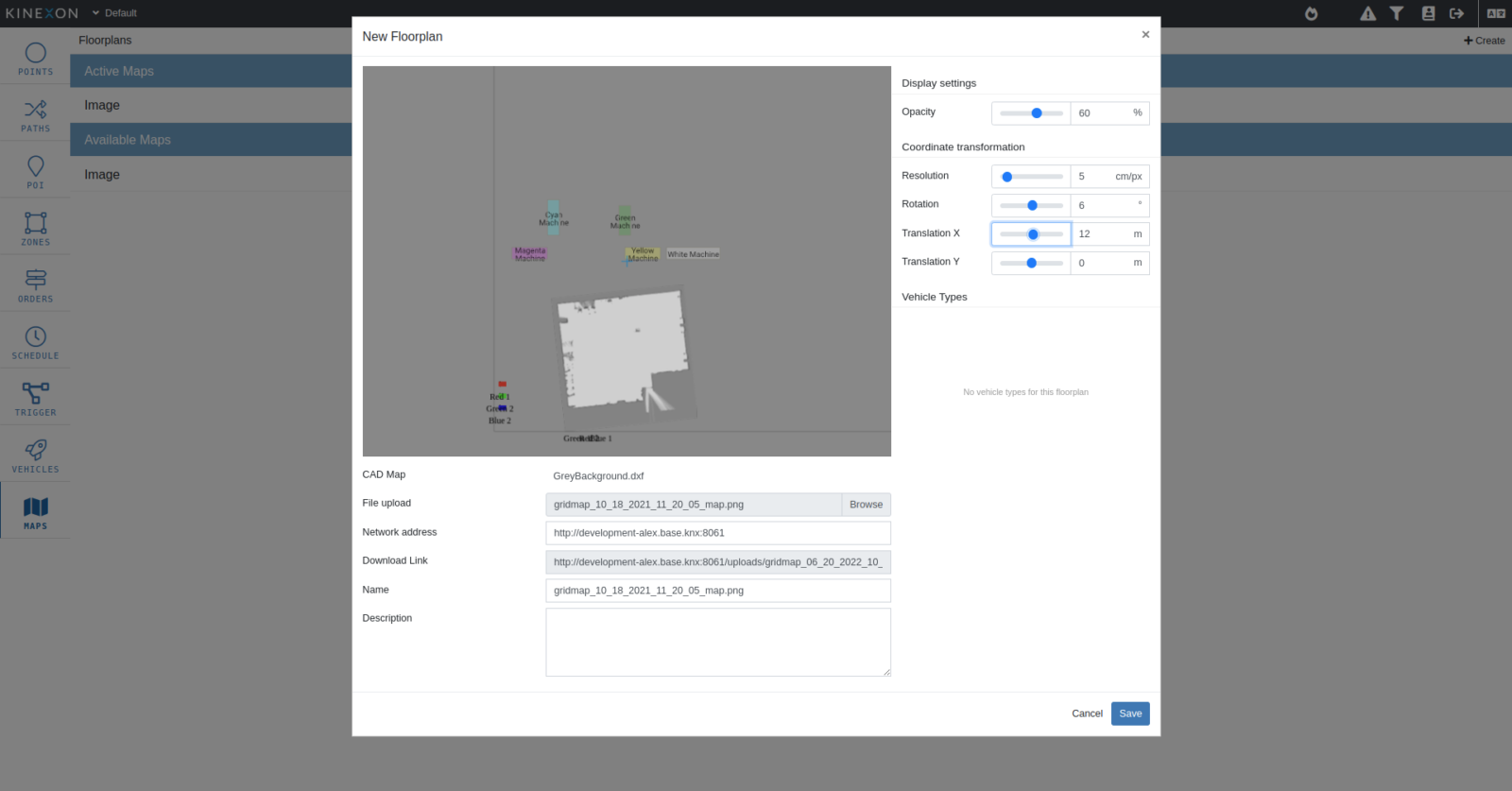

Flexible layout planning is especially important, as your shop floor must meet continually changing requirements. These include seasonal goods or a layout-free assembly line. However, the maintenance costs are often too high.

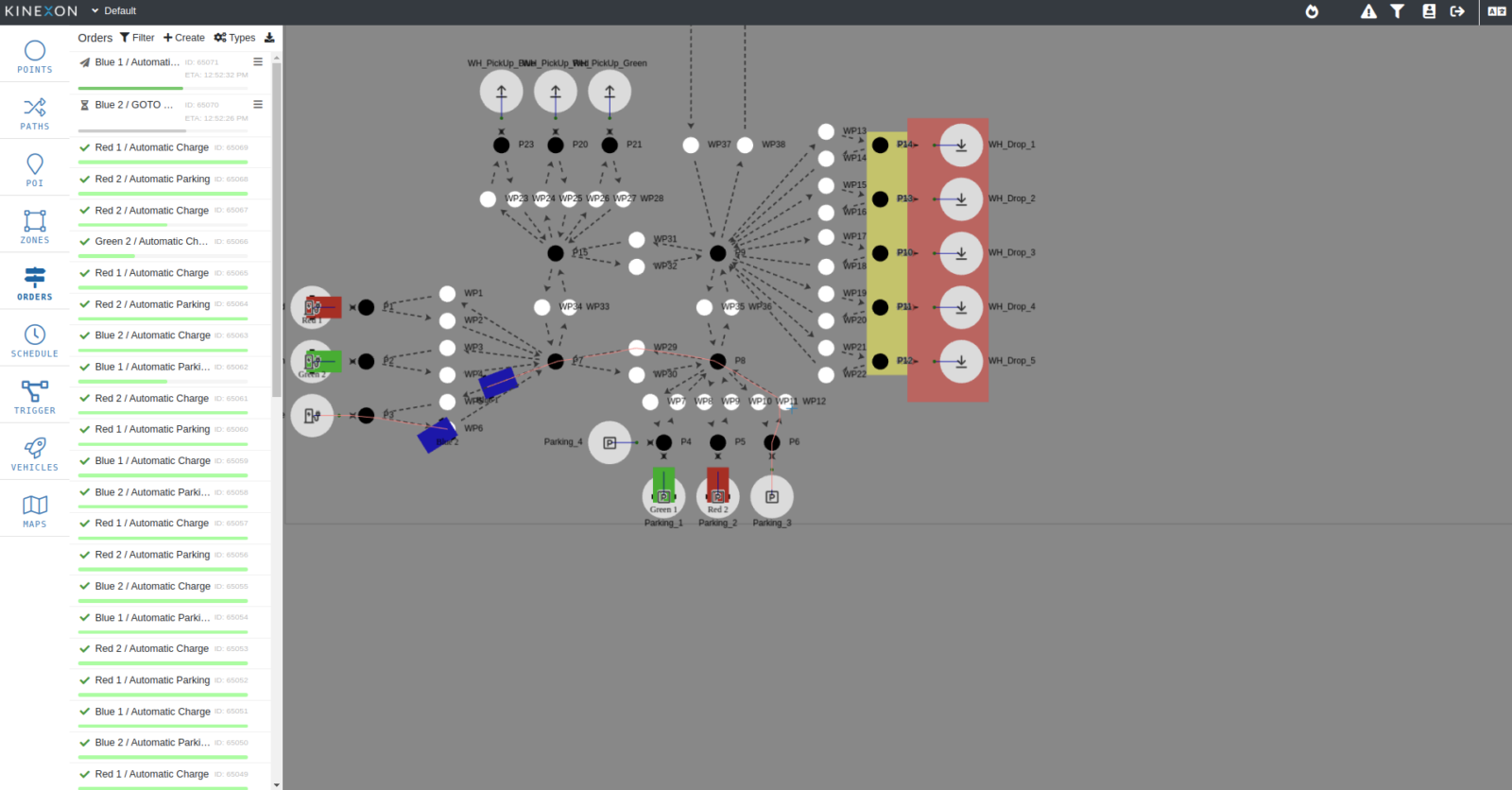

The No-Code application allows shop floor managers to change driving routes, and load carrier positions for the whole fleet within seconds. The creation of zones and waiting areas, in an overarching frontend, enable fast, efficient and predictable routing.

The KINEXON Fleet Manager Creates Connections

Our AMR and AGV fleet manager connects all assets, on the shop floor, to your digital landscape.

Central Product Features

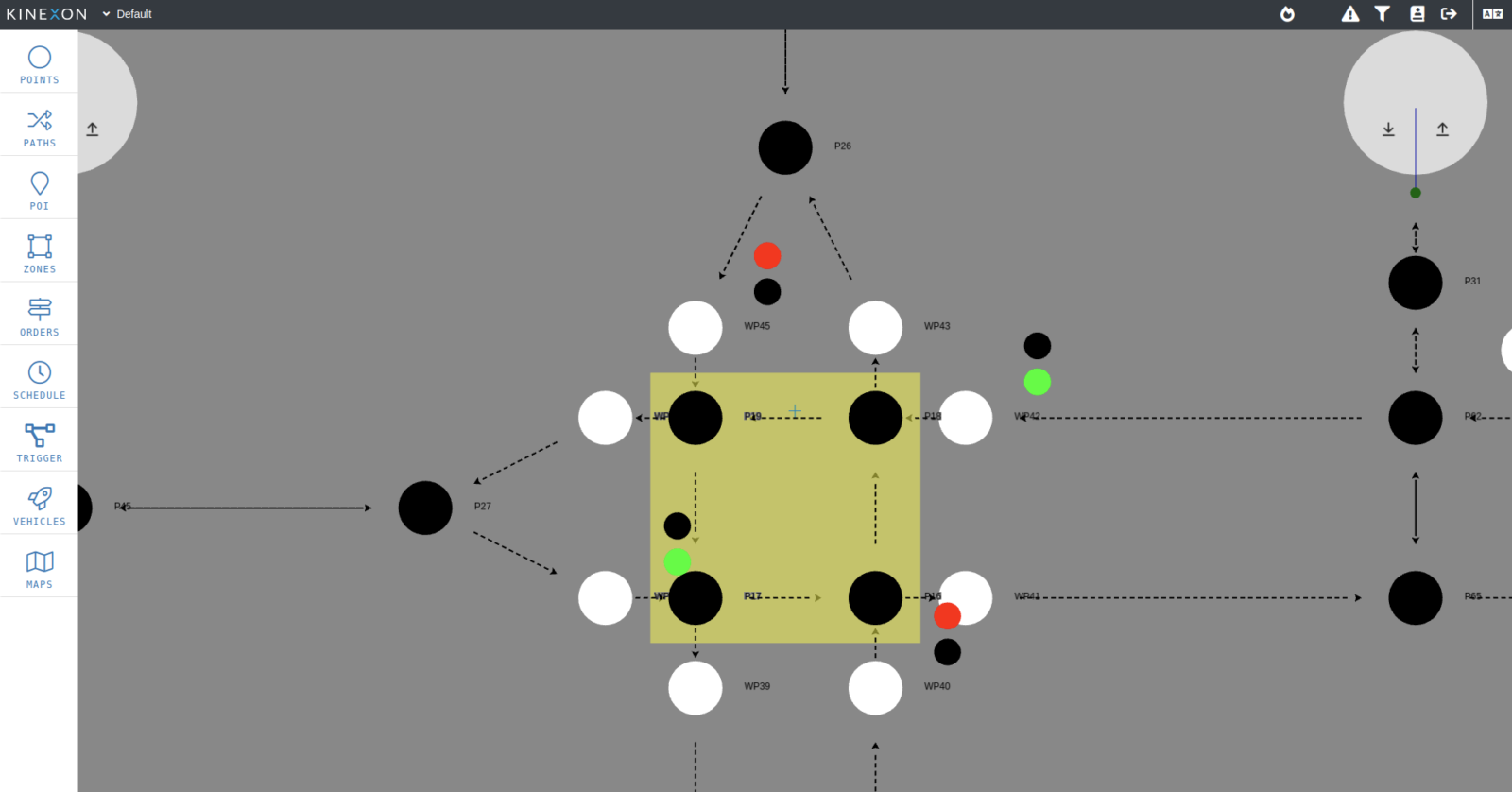

Traffic Control

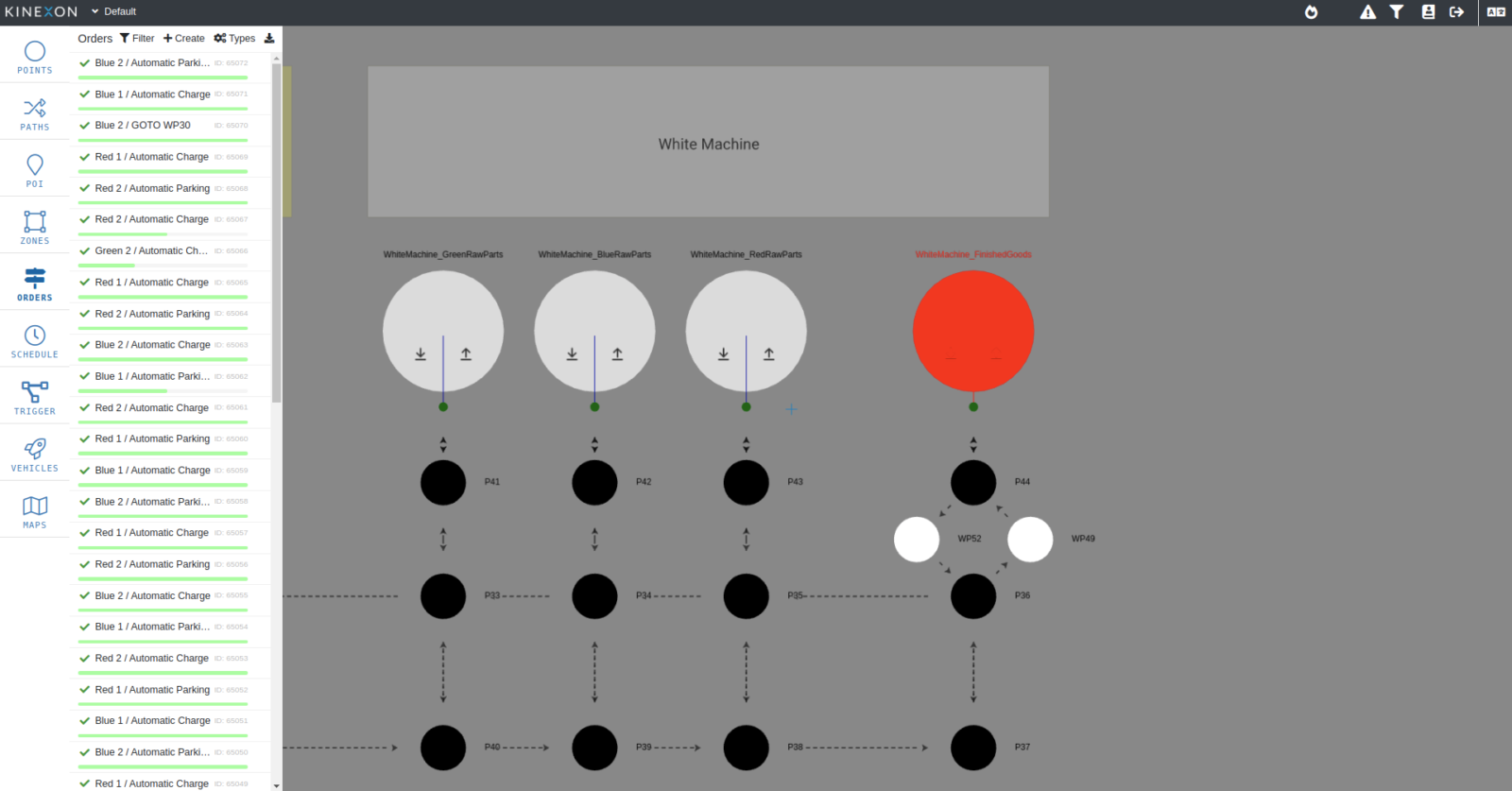

Zones and waiting points to ensure dead-lock free routing of multiple robots.

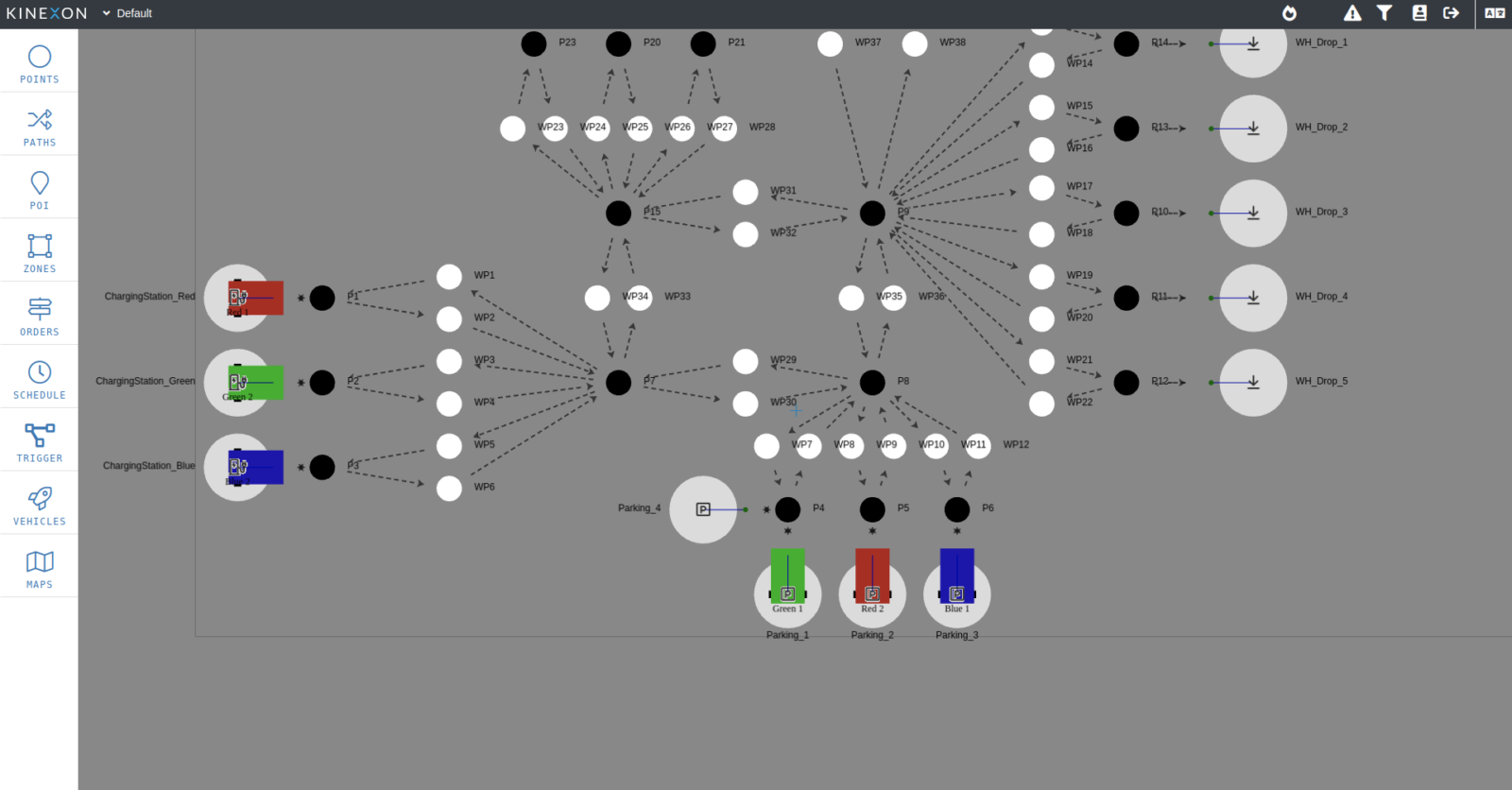

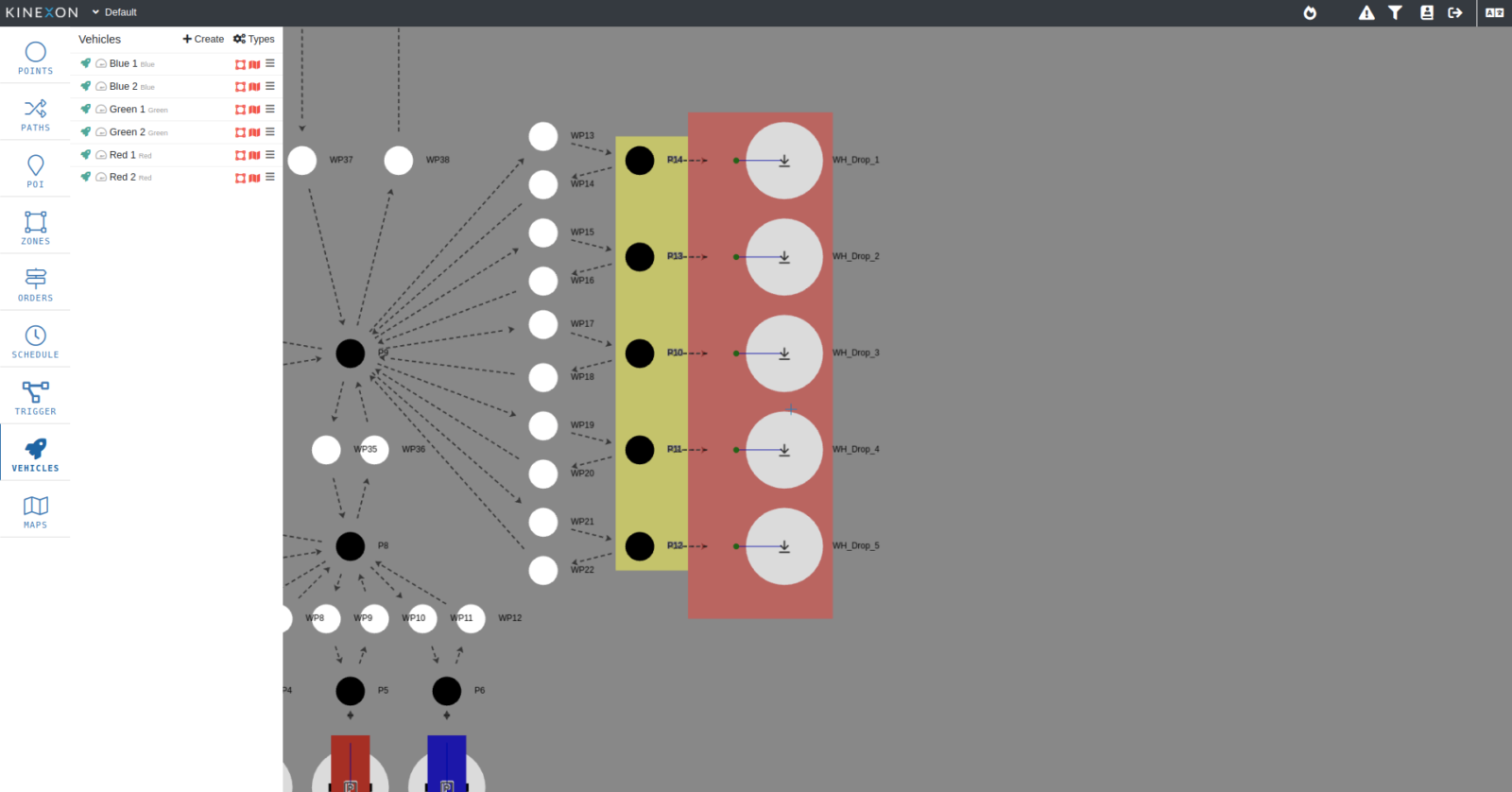

Multiple Robot Types

Define multiple robots, create fleets, assign tasks to specific robot types, and supports VDA5050.

Multiple Zones

Integration of multiple zones, such as “restricted” or “limited capacity” zones.

Central Map Management

Activate and edit maps for multiple robots, all related to a central shop floor layout.

Automatic Charging Strategy

Based on the current state of charge, or the distance to the closest charging station, the fleet manager optimizes availability of the robot fleet.

Flexible Definition of POIs

Define each action for certain POIs„ e.g. pick-up or charge, the robot type or means of fine positioning.

Industries that Benefit most from an Agnostic Fleet Manager

Why KINEXON is the Right Partner for You

VDA5050 Pioneer

We are an early adopter of the VDA5050 communication interface. Our system was built for day one use of the VDA5050 standard, making it possible to run on all iterations. Our solution safe, and your automation is future-proof.

Partner Management

We provide a full-stack solution, that gives you the reins to total independency and makes your customer’s efficiency increase. We offer you a top-layer fleet manager compatible with most of the AMR and AGV operators.

IoT-Experience Center

Want to explore the industrial internet of things live and in an authentic shop floor environment? The IoT Experience Center, is an experimental factory floor to demo and test emerging digital manufacturing technologies.

Client that use our Fleet Management Solution

Continental

With our RTLS solution, KINEXON not only delivered reliable and precise data for Continental. With KINEXON OS, it’s also a versatile, compatible, and dynamically adaptable, real-time IoT solution. Find out more about their success story.

Find out More

AMR & AGV Fleet Management

Our solution offers a control tower for the effective, real-time coordination of AMR fleet operations, with single or multiple vehicle types, on the shop floor.

KINEXON Operating System

Are you looking to integrate other assets? Check out our KINEXON OS to centralize your moving assets’ data. Location data is used to trigger and allocate a pick-up order, within our Fleet Order Management solution, automatically to the closest available AMR/AGV. We leverage indoor location technologies, to generate precise position data of moving assets. The location data can be used to trigger and allocate a pick-up order, in our Fleet Order Management, to the closest available AMR/AGV automatically.