Industry

We Pave the Way to a Smart Factory and Hold the Key to Industry 4.0

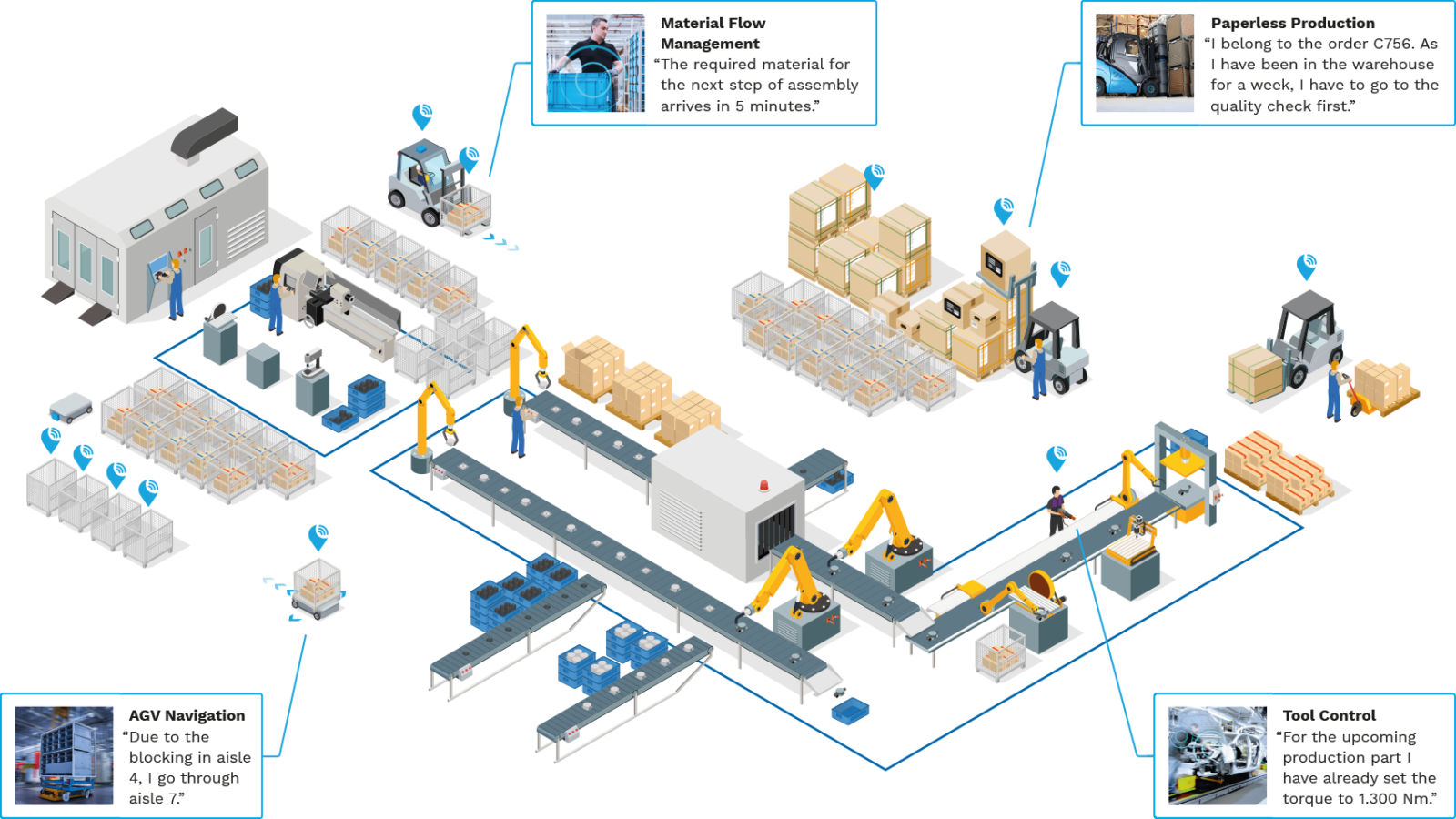

KINEXON delivers concrete and specialized real-time IoT solutions for your move to Industry 4.0 standards. The combination of a high-precision real-time localization system (KINEXON RTLS) and location-based process automation software (KINEXON OS) interconnects and intelligently controls the shop floor. This creates transparency and the potential to optimize and automate processes. And is a central objective of Industry 4.0.

In our latest case study with Continental, you can find out how this can be implemented in practice.

BMW relies on KINEXON to take its production to the next level.

If you’re interested in this topic and want to dive deeper, we highly recommend downloading the BMW case study for more in-depth insights.

“The seamless localization and networking of moving objects are key technologies in the shift to a digitalized shop floor! “For me, this is the first and central step into Industry 4.0. “The second is the intelligent processing of data about locations and statuses. Only then do significant gains in efficiency beckon.”

How Kinexon Transforms Your Factory Into a Smart Factory

Choose Your Manufacturing Applications:

Protection against COVID-19

KINEXON SafeZone is the world’s most trusted digital solution to mitigate the spread of COVID-19. Learn here more about our ultra-precise contact warning and highly efficient contact tracing solution to protect people, employees and operations!

Order Tracking and Process Management

Automated Order Tracking and Process Management for Smarter Manufacturing

Container Management

Automated container management uses precise RTLS data on container location and status on the shopfloor to improve overall container transparency and utilization.

Paperless Production

Paperless and location-based generation of relevant real-time data on moving assets